Beskyttelseserklæring: Dit privatliv er meget vigtigt for os. Vores virksomhed lover ikke at videregive dine personlige oplysninger til ethvert udstrækning uden dine eksplicitte tilladelser.

model nr.: 76.2-152.4

Ansøgning: Pipe

Processing Plastic Type: Pe, Pp, Hdpe, Ppr

status: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 33:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Hotels, Machinery Repair Shops, Farms, Retail, Printing Shops, Food &Amp; Beverage Shops, Other

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Pump, Plc, Gearbox, Screw

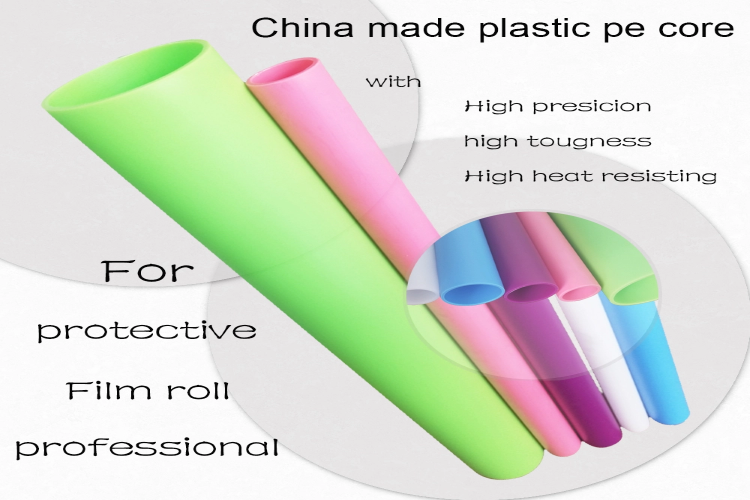

Product Type: PE Pipe

Screw No.: Single-screw

Automation: Automatic

Computerized: Computerized

Certificering: ISO9001:2008

Customized: Customized

Condition: New

Navn: PE Core Pipe Making Machine

Emballage: Wooden Pallet

Transport: Ocean

Havn: Shanghai Port

Betalings type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

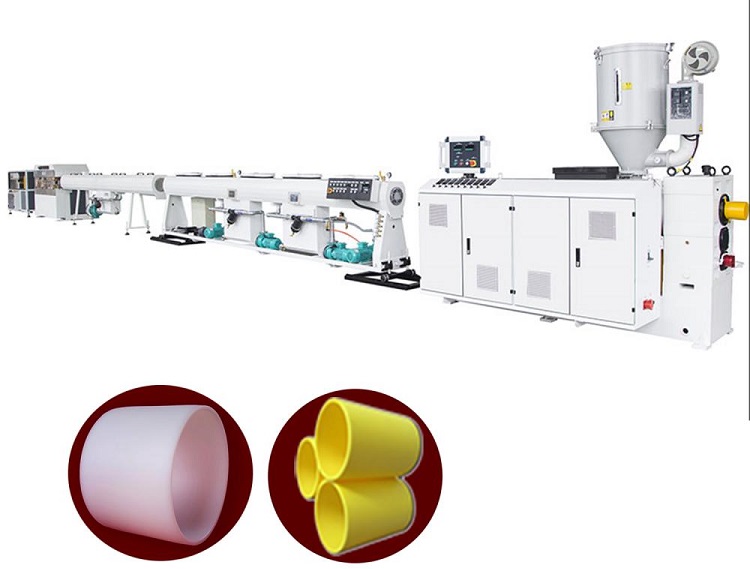

PE plastic core pipe extrusion equipments

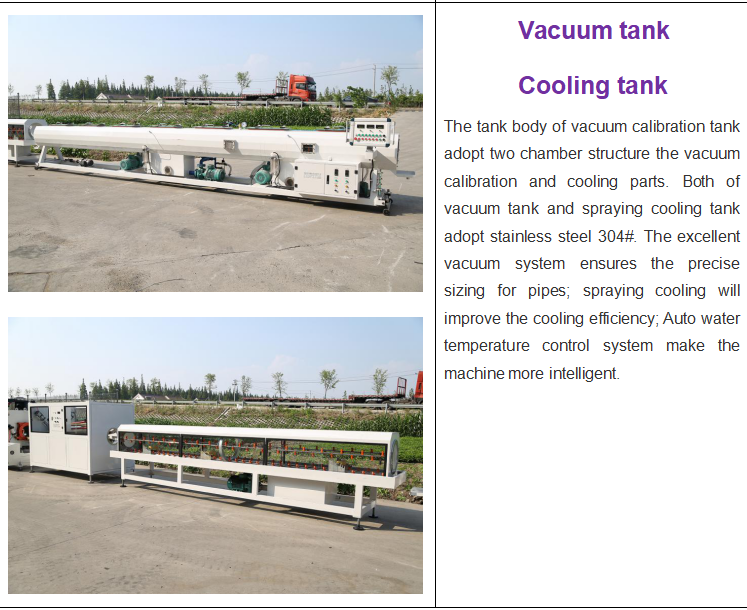

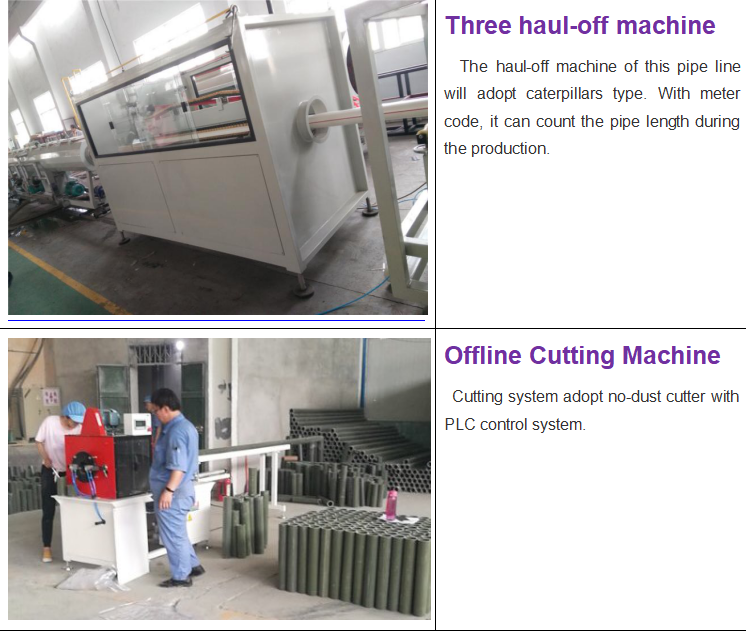

PE plastic core pipe making machine/PE core pipe extrusion line/PE core pipe production line is mainly used to manufacture for PE plastic pipe, and GF series tube auxiliary equipments production line can also be used to process other plastic. Extruder and GF series tube auxiliary equipments production line take the features of advantages, reliability applicability together, and provide strong certification for high-quality plastic tube for customers. This production line adopts high-efficiency single-screw extruder, equipped with extrusion mould, vacuum shaping tank, spray cooling tank, haul-off, planetary cutter and controlled by PLC micro-computer system.

PE plastic core pipe extrusion equipments photos

1. Single screw extruder: model SJ65/33

2. Cylinder and screw material: 38CrMoAlA, after nitriding and grinding, the depth of nitriding layer is more than or equal to 0.6mm, which has sufficient strength, wear resistance and corrosion resistance;

3. Cylinder and screw structure: barrier screw, asymmetric slotted barrel design.

4. The gearbox is equipped with strong thrust bearing and high torque output;

5. Temperature control table of OMRON

6. ABB or Siemens brand inverter

7. Schneider or Siemens AC contactor

8. Siemens Bede motor

9. Diameter of screw: Φ 65mm

10. Length diameter ratio of screw: 33:1

11. Driving motor power: 160kW high speed screw

12. Gearbox: high torque, low noise, hard tooth surface grinding reducer is equipped with external cooling circulation system

13. Heating power of barrel: 6*5kw (cast aluminum heating ring)

14. Cooling power : 6 × 0.25kw forced air cooling

15. The output is 120-180kg / h

Zhangjiagang Huade Machinery

Packaging

Exhibition

Certification

Produktkategorier : HDPE PP Pipe Extrusion Line

Mobil websted

Beskyttelseserklæring: Dit privatliv er meget vigtigt for os. Vores virksomhed lover ikke at videregive dine personlige oplysninger til ethvert udstrækning uden dine eksplicitte tilladelser.

Udfyld mere information, så det kan komme i kontakt med dig hurtigere

Beskyttelseserklæring: Dit privatliv er meget vigtigt for os. Vores virksomhed lover ikke at videregive dine personlige oplysninger til ethvert udstrækning uden dine eksplicitte tilladelser.