Ráiteas Príobháideachais: Tá do phríobháideacht an -tábhachtach dúinn. Geallann ár gcuideachta gan do chuid faisnéise pearsanta a nochtadh d'aon fhairsinge le do cheadanna sainráite.

Múnla Uimh.: 500-630

Branda: HUADE

Iarratas: Bar, Pipe

Processing Plastic Type: Pe, Pp

Stádas: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 90

Screw Length To Diameter Ratio: 38:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Germany, Philippines, Saudi Arabia, Mexico, Russia

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Competitive Price

Out-of-warranty Service: Video Technical Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Philippines, Mexico, Russia, Spain, South Korea, Sri Lanka

Applicable Industry: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Energy &Amp; Mining

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Bearing, Motor, Pump

Pacáistiú: Wooden Pallet

Táirgiúlacht: 800

Iompar: Ocean

Áit Tionscnaimh: CHINA

Cumas Soláthair: 10

Teastas: CE

Cód HS: 84778000

Port: Shanghai Port

Cineál Íocaíochta: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

315-630mm HDPE water pipe extrusion line

315-630mm HDPE tube production line / making machine

Diameter Range (mm): 315 355 400 450 500 560 630 wall thickness by request

Main Extruder Motor Power: 3280kw

Line Space Occupation: 65mx5mx3m

Capacity: 800-1000kg/h

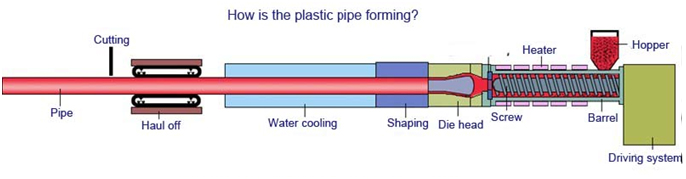

Introduction of HDPE 315-630mm big size pipe production line

The unit consists of single screw extruder , die head, vacuum cooling tank, haul-off machine, planetary(swarf less/ chip free cutter / no dust cutter) cutting machine, winder stacker and so on.

Turn-key solution can be provided, like laser printer ,crusher, shredder, water chiller, air compressor etc. to achieve high-grade and automatic tube production.

Characteristics of PE 6315-630mm Pipe extrusion line cost

Process Flow for PE 630-1200mm pipe making machine :

Raw material+ master batches → Mixing → vacuum feeding → material dryness → single screw extruder →color string extruder → spiral mould → vacuum calibration tank → spray cooling water tank →spray-code printer → haul-off → no-dust cutter → Double disc Winding/ Stacker → finished product inspecting &packing

More images for PE 630-1200mm pipe production line

Single screw extruder

Model :SJ120/38 extruder of HDPE 630-1200MM extrusion line

Diameter of screw: Φ 120mm

Length diameter ratio of screw: 38:1

Driving motor power: 355kW high speed screw

Die head and mould(including the bush,pin and calibrator)

Materials: 40Cr Steel

Structure: Spiral or Basket

Single cavity design

Single layer design

Vacuum Calibration Tank

length: 1000mm

Tank materials: 4mm 304 S. S.Materials

Double-chamber structure vacuum and cooling

Water temperature and level controlling technology

High pressure and stable water jet

Pressure protection design

6 caterpillar Haul-Off machine :

ABB Frequency motor driving

Upper and lower caterpillar is driven separately by the frequency inverter

Fast change type pads

High friction fact and anti-wear out silicon rubber Pads

Metering counter

Cutter:

Non-dust cutter, Blade rotates around pipe and cut off pipe with smooth surface.

Synchronous control

Cast aluminium fixture unit

High Quality Alloy Blades

Smooth Cutting surface

Servo motor Synchronous control

Stacker

Stainless steel 304 as touching material

Discharge driving by air cylinder

Packaging of PE 630-1200mm pipe production line

Exhibition of PE 630-1200mm pipe production line

Catagóirí Táirge : HDPE PP Pipe Extrusion Line

Suíomh Soghluaiste

Ráiteas Príobháideachais: Tá do phríobháideacht an -tábhachtach dúinn. Geallann ár gcuideachta gan do chuid faisnéise pearsanta a nochtadh d'aon fhairsinge le do cheadanna sainráite.

Líon isteach tuilleadh faisnéise ionas go bhféadfaidh sé sin teagmháil a dhéanamh leat níos tapa

Ráiteas Príobháideachais: Tá do phríobháideacht an -tábhachtach dúinn. Geallann ár gcuideachta gan do chuid faisnéise pearsanta a nochtadh d'aon fhairsinge le do cheadanna sainráite.