Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

ʻO Brand: huade

Ka hoʻohana: Granules

Processing Plastic Type: Pvc

Kūlana: New

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 132:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, United States, Peru, Mexico

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Indonesia, India, Mexico, Russia, Kenya, Uae

Applicable Industry: Building Material Shops, Manufacturing Plant

Marketing Type: Hot Product 2019

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor

Packaging: film wrap and fixed in container

'Ohanahana: 300-350kg

Nā kaʻa: Ocean

Kahi o ka hoʻomaka: china

Ka hoʻolakoʻana i ka pono: 10set per month

Palapala: CE

HS Code: 84778000

ʻO Port: Shanghai

ʻO keʻano o ka uku: L/C,T/T

ʻO Incoterm: FOB,CFR

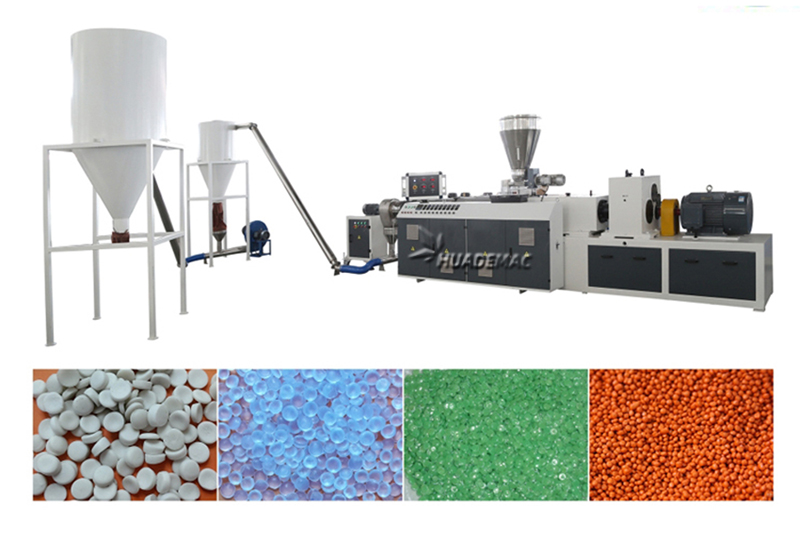

PVC Hot Cutting Pelletizing Line

Plastic Extruder/Plastic Machine/Hot-Cutting Compound PVC Granulating Line Pelletizing Line

PVC Compounding Hot Cutting Pelletizing Line/Recycled PVC Pelletizing Machine

Features:

1. Conical twin screw extruder, which is very suitable for processing PVC powder with high capacity

2. Granulation style: on the mold surface eagerly, cutting to ensure a good state.

3. Auxiliary equipment:pellet cooling and classification, its capacity can be from 150kg / h to 700kg / h.

4. According to material formulation, we choose the most reasonable screw to achieve the best plasticity state purposes, and good product quality.

Process:

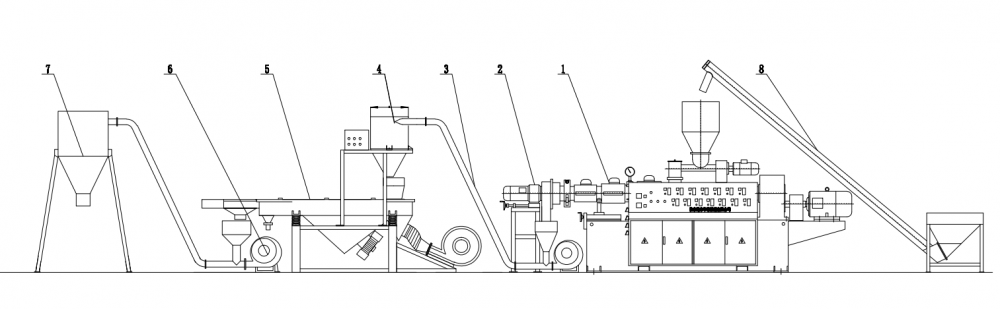

PVC powder---Plastic mixer(optional)---twin screw extruder---extrusion die mould---Pelletizer air cooling system---vibrating sieve(optional)---Storage Bin.

Technical Data:

|

Extruder |

SJZ51/105 |

SJZ55/110 |

SJZ65/132 |

SJZ80/156 |

SJZ92/188 |

|

Main Motor Power |

18.5kw |

22kw |

37kw |

55kw |

110Kw |

|

Production capacity |

120kg/h |

180kg/h |

250kg/h |

350kg/h |

700kg/h |

Die Head and Hot Cut Pelletizer

Vibrating Sieve

Air cooling & Storage Bin.

The PVC mixer is also necessary for mixing PVC, CACO3 and other addictives.

Nā huahana huahana : Plastic Recycling Granulating Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.