Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: C300

Screw No.: Double-screw

Automation: Automatic

Computerized: Computerized

Certification: ISO9001:2008

Customized: Customized

Condition: New

Name: PVC Ceiling Panel Profile Line

Packaging: Wooden Pallet

Nā kaʻa: Ocean

ʻO Port: Shanghai Port

ʻO keʻano o ka uku: L/C,T/T,D/P

ʻO Incoterm: FOB,CFR,CIF,EXW

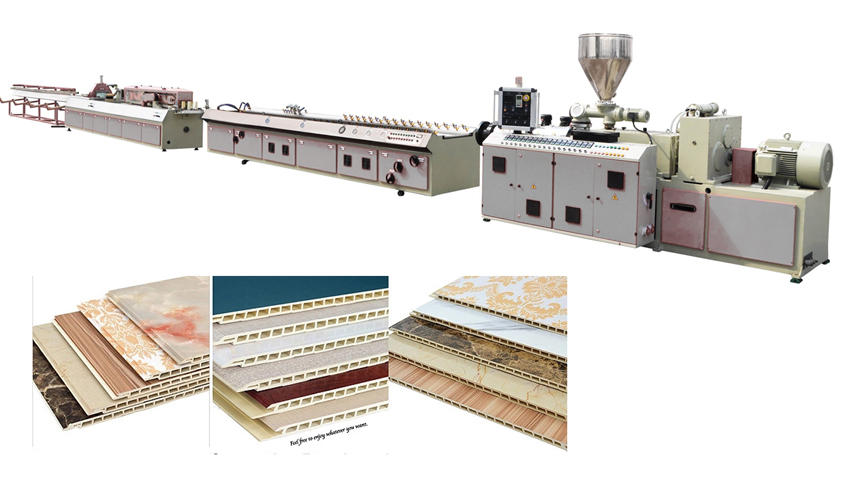

PVC ceiling panel profile production line

PVC Ceiling Making Machines

(1) It is mainly used for making PVC/UPVC profile, ceiling, panel for decoration with different profile break-section moulds.

(2) It can also produce Wood+ PVC profiles with different screws in the extruder.

The production line includes auto feeder, plastic extruder, mould, vacuum forming table, haul off unit, auto cutting machine, stacker.

Auxiliary equipments: mixer, crusher, pulverizer, lamination machine, hot stamping machine, printing machine, air compressor and so on.

The working process of PVC ceiling making machines:

Raw material → mixing → feeder→ double screw extruder → mold → vacuum calibration table → (hot stamping) → haul-off unit → cutting machine → stacker

PVC ceiling panel profile production line photos

Twin screw extruder

Ceiling panel die head

Vacuum calibration table

2 caterpillar haul off machine

Saw cutter

Final products

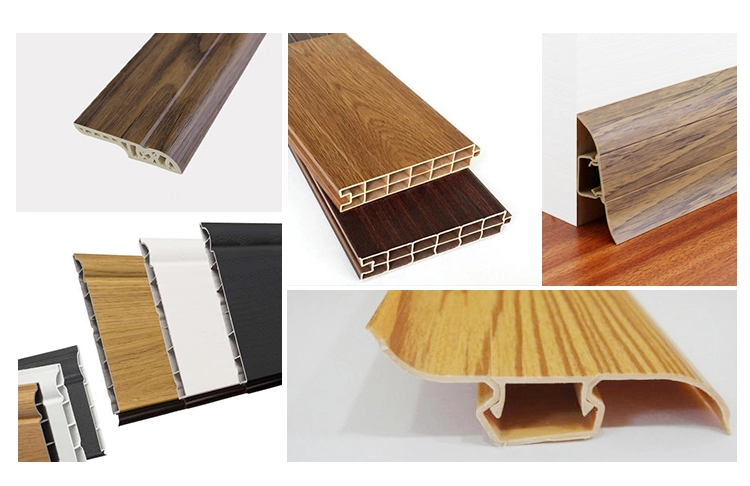

Other products

Packaging

Zhangjiagang Huade Machinery

Nā huahana huahana : Plastic Profile Production Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.