Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Ka hoʻohana: Pipe

Processing Plastic Type: Pe, Pp, Ppr, Hdpe/Pp, Pe/Pp

Kūlana: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 33:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Energy Saving

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Garment Shops, Machinery Repair Shops, Food &Amp; Beverage Factory, Printing Shops, Food &Amp; Beverage Shops, Advertising Company

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Pump, Gearbox, Screw

Packaging: Wooden Pallet

Nā kaʻa: Ocean

ʻO Port: Shanghai Port

ʻO keʻano o ka uku: L/C,T/T

ʻO Incoterm: FOB,CFR,CIF,EXW

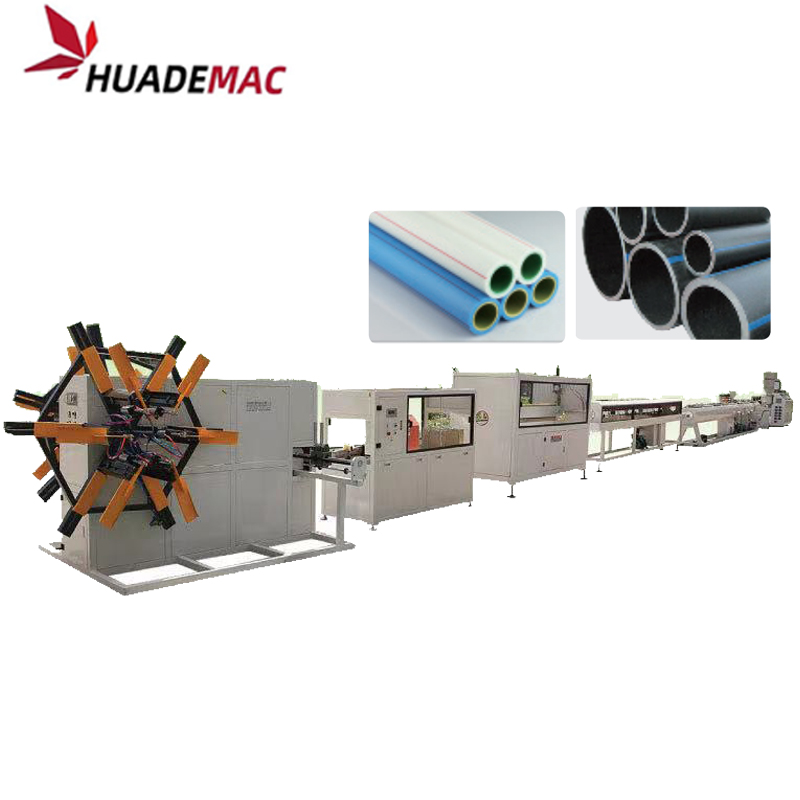

HDPE PIPE PLASTIC EXTRUSION MACHINE COST

HDPE PIPE PLASTIC EXTRUSION MACHINE:

HDPE PP Pipe Extrusion Line is a new product developed by our company by introducing and absorbing foreign advanced technology. HDPE PP Pipe Extrusion Line screw, die and other key components are specially designed according to the characteristics of pp-r. Through the three-layer coextrusion technology, the spiral three-layer co extrusion die with special design is adopted to ensure the uniform thickness of three layers and the thickness of each layer can be adjusted arbitrarily. HDPE PP Pipe Extrusion Line Spiral split die can be equipped with static mixing system. The material layers are fully overlapped with each other. Compared with the traditional support die head, the internal pressure is more uniform. In the form of ABA, the glass fiber in the middle reinforcement layer is arranged regularly, and organically melts with the inner and outer PPR layers to form a whole, which significantly overcomes the overhanging phenomenon of the pure PPR pipe in surface installation, and reduces the linear expansion coefficient of the pipe. Compared with pure PPR pipe of the same specification and pressure grade, it can save material, reduce cost and be more competitive. The production line is equipped with automatic vacuum feeding machine and automatic constant temperature dryer; the designed vacuum sizing and cooling system is made of stainless steel water tank and cooled by multi-stage water mold to ensure the requirements of high-speed production of thick wall pipe and large-diameter pipe. High torque reducer, frequency converter, PLC, touch screen, electric control system, inkjet printer and so on are imported products. New chip free automatic cutting saw, smooth cutting section, high precision, low noise and so on. It can produce HDPE silicon core pipe, ordinary PPR, PE, PEX pipe. Provide process formula and turnkey project.

Characteristics of HDPE PIPE PLASTIC EXTRUSION MACHINE COST:

1. HDPE PP Pipe Extrusion Line is mainly used for pipe production with PPR resin as raw material. 2. The design of slotted feeder barrel and barrier screw can improve the plasticizing effect. 3. High extrusion rate, low melt temperature and uniform temperature. 4. Barrier type two pole mixing, i.e. special screw for day, slotting barrel. 5. HDPE PP Pipe Extrusion Line Equipped with a new type of secondary split die, with the characteristics of low temperature and low pressure extrusion: water film sizing sleeve, to ensure the high-speed production of pipes. 6. HDPE PP Pipe Extrusion Line is controlled by PLC, and PPR cold and hot water pipe production line manufacturer has good man-machine interface. 7. The marking line can be selected to extrude to produce the pipe with color mark. The production line can produce PE pipe by changing mould.

Drying of raw materials→ Extrusion molding → Vacuum sizing → Spray cooling → Haul-off → Fixed length cutting → Pipe filling and unloading

HDPE PIPE PLASTIC EXTRUSION MACHINE COST photos

Exhibition of HDPE PPR water pipe line production machine

Nā huahana huahana : PPR PPRC Pipe Extrusion Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.