Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: 16-63mm

Ka hoʻohana: Pipe

Processing Plastic Type: Pe

Kūlana: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 33:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Manufacturing Plant

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Bearing

Nā kaʻa: Ocean,Air

ʻO Port: shanghai

ʻO keʻano o ka uku: T/T,L/C

ʻO Incoterm: CFR,FOB,CIF

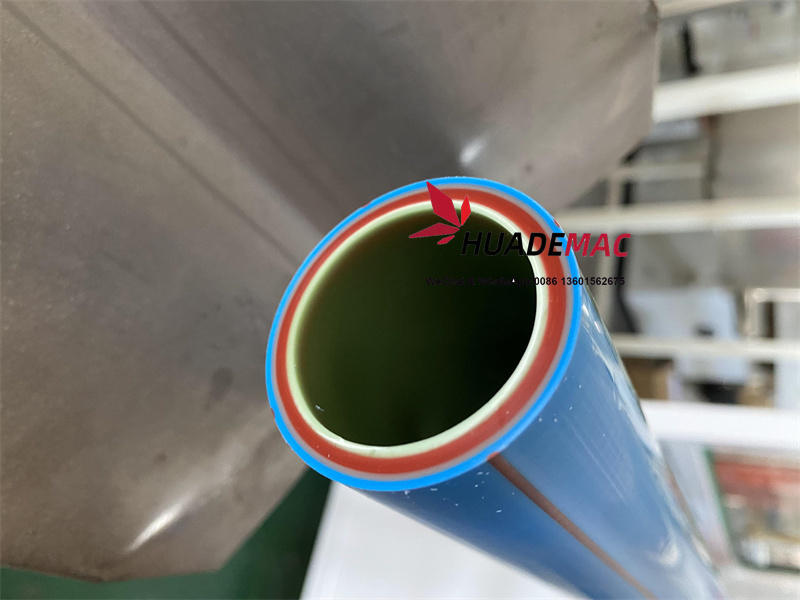

4 layers PPR IPS PPH pipe making machines are used to manufacture polypropylene homopolymer (PPH) pipes. These machines are designed to extrude molten polypropylene through a die to form pipes of various sizes and dimensions.

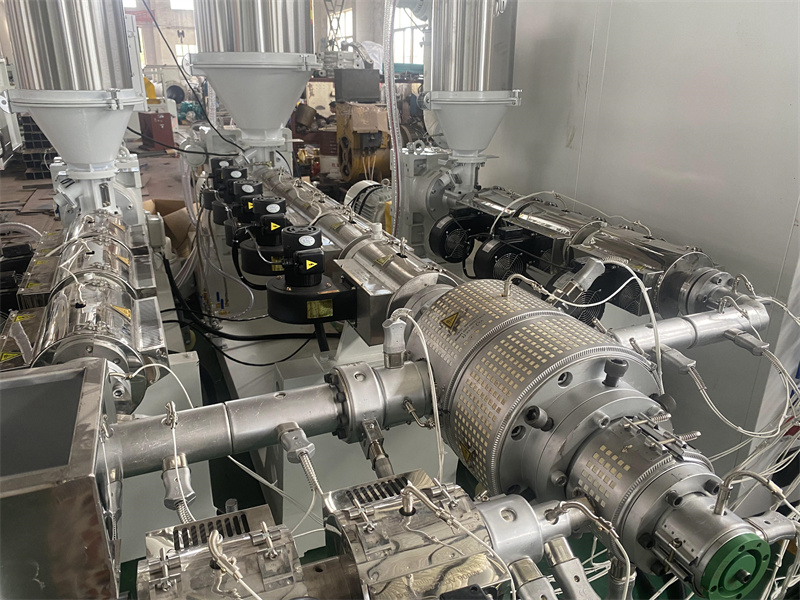

The PPH pipe making machine typically consists of the following components:

1. Extruder: The extruder is the main component of the machine, responsible for melting and homogenizing the polypropylene resin. It consists of a barrel and a screw, which rotate to generate heat and pressure required for melting the resin.

2. Die head: The die head is responsible for shaping the molten resin into a pipe. It has a specific design to control the size and dimensions of the pipe being produced.

3. Cooling system: After the pipe is extruded from the die head, it needs to be cooled down to solidify. The cooling system usually includes water tanks or cooling fans to rapidly cool the pipe.

4. Haul-off unit: The haul-off unit is used to pull the pipe out of the machine at a constant speed. It consists of belts or caterpillar tracks that grip the pipe and move it forward.

5. Cutting unit: Once the pipe is pulled out of the machine, it needs to be cut into desired lengths. The cutting unit can be equipped with a saw or a guillotine cutter to achieve precise and clean cuts.

6. Control system: The machine is controlled by a control panel, which allows the operator to monitor and adjust various parameters such as temperature, speed, and pressure.

PPH pipe making machines are widely used in the construction industry for the production of pipes used in plumbing, drainage systems, and irrigation. These machines are known for their high production capacity, efficiency, and the ability to produce pipes of consistent quality.

Nā huahana huahana : PPR PPRC Pipe Extrusion Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.