Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: 110-250mm

Ka hoʻohana: Pipe

Processing Plastic Type: Pvc

Kūlana: New

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 80

Screw Length To Diameter Ratio: 156:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Kenya, South Africa, Kazakhstan, South Korea, Ukraine, Indonesia, Pakistan, India

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Energy Saving

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Brazil, Saudi Arabia, Malaysia, Sri Lanka, Bangladesh

Applicable Industry: Building Material Shops, Restaurant, Home Use, Printing Shops, Construction Works

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Gear, Other, Gearbox

Condition: New

Automation: Automatic

Computerized: Computerized

ʻOiaʻiʻo: Iso9001:2008

Customized: Customized

Product Type: Pvc Pipe

Screw No.: Double-Screw

Inoa: Pvc 3 Layer Co-Colour

Packaging: Wooden Pallet

Nā kaʻa: Ocean

ʻO Port: Shanghai Port

ʻO keʻano o ka uku: L/C,T/T

ʻO Incoterm: FOB,CFR,CIF,EXW

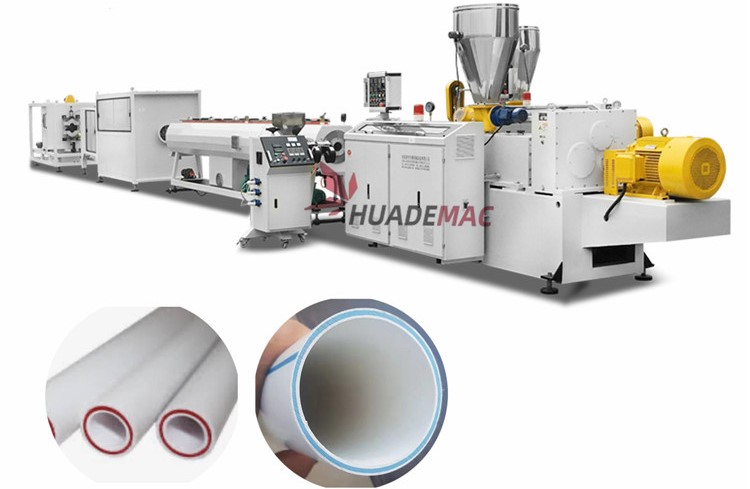

PVC 3 layer co-extrusion production line

PVC pipe manufacture machine includes two main extruders: one is for making outer&inner layers and another one is for making middle layer.

PVC pipe manufacture machine is mainly used in producing of PVC pipes with various tube diameter and wall thickness in the aspects such as

the agricultural, constructional, and cable laying etc. PVC pipe manufacture machine is composed of the conical twin-screw extruder, vacuum modes such

as two claw, three claw and so on. Choose the saw blade cutting type or the planetary cutting type. It is additionally attached

manufacturer of the inner wall spiral coil according to the client requirements. Produce inner wall spiral pipe, inner wall hollow

and core foam pipe, ect.

PVC 3 layer co-extrusion production line photos

Screw Feeder

SJ65/132 Extruder

• Capacity: 200-250kgs/h

• Motor power: 37kW

• Material of screw & Barrel: 38CrMoAl & Bimetallic

Die-head

• 40Cr material

• Size :50 63 75 90 110 160 200mm

•Complete set include extrusion die head, Slotting & water ring type calibration sleeve

Vacuum Sizing Box

• 4kw water pump and 4kw vacuum pump

• length 6000mm

Haul-off Machine

• Upper and lower caterpillar is driven separately by the frequency inverter

•High friction fact and anti-wear out silicon rubber Pads

• Metering counter device

Planetary Cutter

• Planetary saw cutter enter knife by hydraulic drive

• Cutting saw: steel alloy, specific for cutting U-PVC pipe.

• Equipped cast aluminum compacted block for accurate cutting

• Synchronous control

Belling Machine

• Blow type: internal air blow and external mould compacted calibration, make U, R and Z type sockets;

• Siemens PLC controlling: Automation& Remote Function: for centralized Controlling

Nā huahana huahana : PVC Muti-layer Pipe Production Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.