Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: 50-110mm

Packaging: Wooden Pallet

Nā kaʻa: Ocean

ʻO Port: Shanghai Port

ʻO keʻano o ka uku: L/C,T/T

ʻO Incoterm: FOB,CFR,CIF,EXW

2 cavity CPVC PVC pipe manufacturing machine

Main Components:

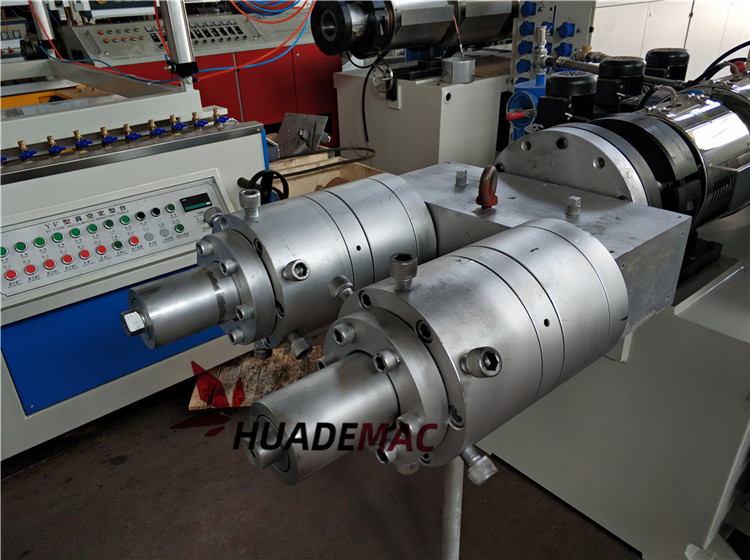

1. SJZ-65/132 Twin Screw Extruder (With Spiral Hopper Loader)

2. Extruder Die Head(75-160mm)

3. Vacuum Cooling Water Tank(Two Section)

4. Three Claw Traction Machine

5. Planetary Cutter

6. Pipe Stacker

The screw extruder and traction machine adopt imported AC frequency control device.

The vacuum pump and traction motor both adopt advanced products.

The haul-off machine has many models, such as two-claw, three-claw, four-claw, six-claw etc.

Processing flow of plastic pvc pipe making machine extrusion line:

PVC powder + additive → spring feeding → twin screw extruder → mould and calibrator→ vacuum forming machine → haul off machine → cutting machine → discharging rack

Two cavity PVC pipe extrusion line photos

Extruder

Die-head

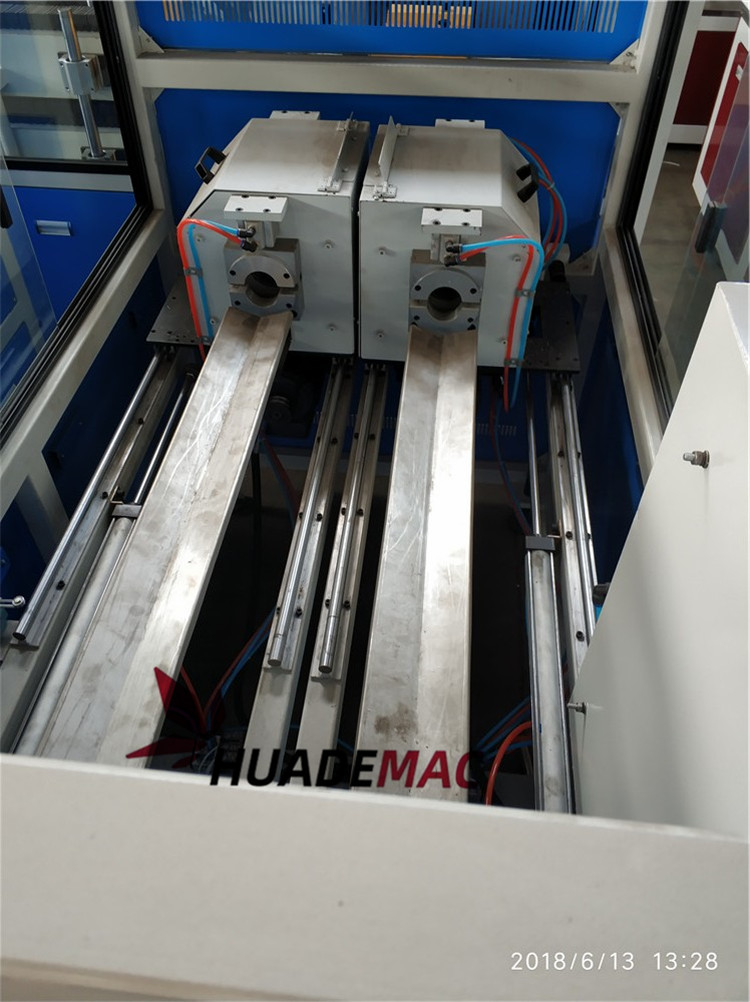

Vacuum Sizing Box

Haul-off Unit

Cutter

Stacker

Packaging

Exhibition

Nā huahana huahana : PVC Conduit Pipe Production Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.