conversion control

Adatvédelmi nyilatkozat: Az Ön adatvédelme nagyon fontos számunkra. Cégünk megígéri, hogy nem tesz közzé személyes adatait semmilyen kitettségnek az explicit engedélyekkel.

Model szám.: 20-38

Márka: huade

Alkalmazás: Pipe

Processing Plastic Type: Pp, Pe, Hdpe/Pp, Ldpe

Állapot: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 45

Screw Length To Diameter Ratio: 30:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Bangladesh, South Africa, Kazakhstan

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Out-of-warranty Service: Video Technical Support, Spare Parts, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Germany, Kenya, Argentina

Applicable Industry: Food &Amp; Beverage Factory, Construction Works, Manufacturing Plant

Marketing Type: Hot Product 2019

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Bearing, Gearbox

Termelékenység: 80

Szállítás: Ocean

Származási hely: China

Ellátási képesség: 10

Bizonyítvány: CE

HS-kód: 84778000

Kikötő: Shanghai

Fizetési mód: L/C,T/T

Incoterm: FOB,CFR,CIF

Extruder model: SJ45/30

Forming moulds: 42 pairs of modules =84 pieces

Size:16-20-25-32-40mm

capacity:30-70kg/h

Line occupation:7mX4mX3m

Product Description:

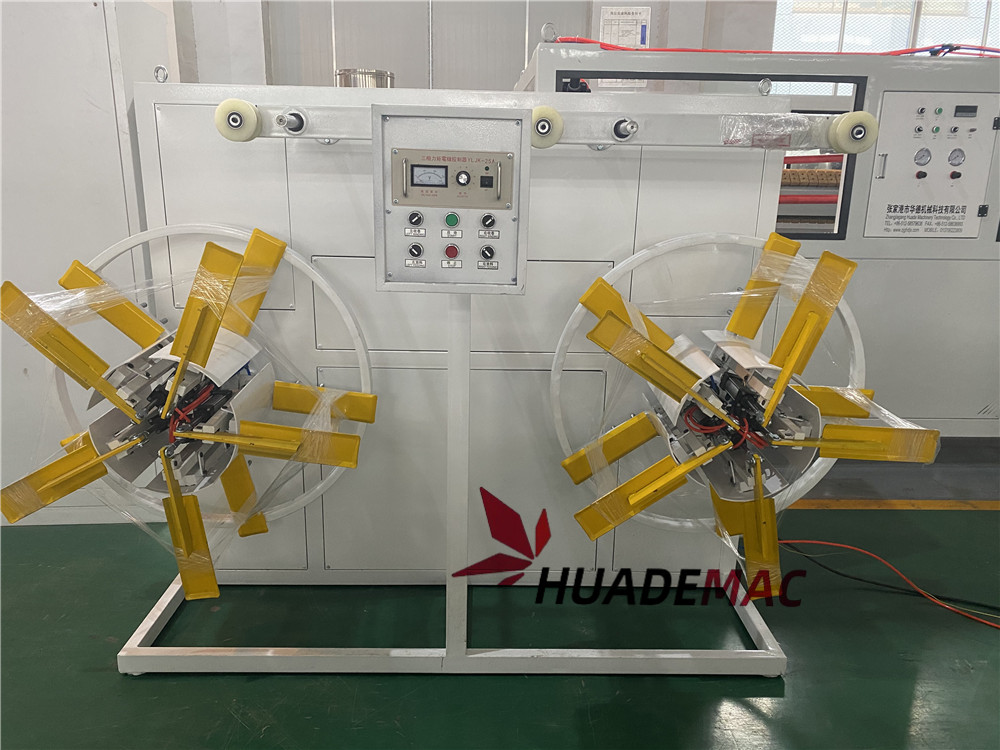

PP PE PVC single wall corrugated pipe extrusion line

It is mainly composed of the extruder, extruder die-head, corrugated pipe forming machine, forming machine chain mould, and winding machine can be added if customers need.

Use: single wall flexible corrugated pipe machine has features of high temperature resistance,resistant to corrosion and

abrasion,high intensity,good flexibility,etc.

Features: They are widely used in fields of auto wire,electric thread-passing pipes,circuit of machine tool,protective pipes of lamps and lanterns wire,tubes of air conditioner and washing machine,etc.

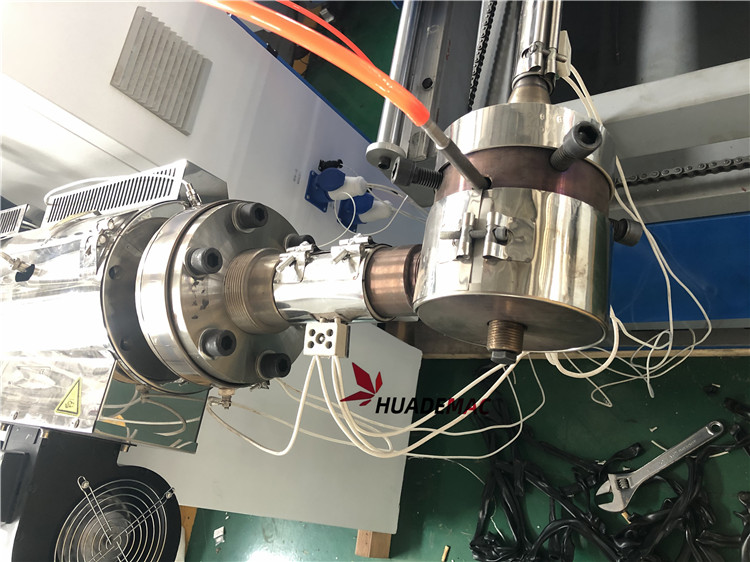

Single Screw Extruder

Driven motor: It is main part of single screw extruder. We'd better choose good brand AC type driven motor matching with inverter

controll for saving power running cost.

Gear recuder box: It is used for connecting motor and for reducing rotating speed of screw through size and teeth of gear changing

in the gear box.

Screw and barrel: It is most important part of single screw extruder. Design of single screw is becoming to special and customzied

now due to many different kind plasic materials are using. The surface of screw should be paint double alloy for anti-wear.

Casting aluminum heater: It is used for heating barrel and screw which ensure mixed PVC/PE/PP resin material can be plasticizing and melting under the suitable temperature.

Cooling blower : It is used for cooling barrel and screw. if temperature of screw and barrel will be excess setting

temperature,cooling blowers start to work for cooling barrel which avoid PVC/PE/PP material resolved in the inside of barrel.

Hopper : It is used for keep the mixed PVC/PE/PP resin material in the silo and make sure material can be into barrel

continuously. It is like a material transport station.

Control Cabinet: It is used for control whole cornic double screw extruder running by switchs or PLC programes according to different circuits control required.

Die head and Mould

1 Material: 40Cr

2. Inner Diameter of corrubated: 7mm

3 Die head stainless steel heating ring, one heating zone

4 42 pairs of modules = 84 pieces

Packing & Delivery of PP PE single corrugated Pipe Extrusion Line

termék kategóriák : Single Wall Corrugated Pipe Production Line

Mobil webhely

Adatvédelmi nyilatkozat: Az Ön adatvédelme nagyon fontos számunkra. Cégünk megígéri, hogy nem tesz közzé személyes adatait semmilyen kitettségnek az explicit engedélyekkel.

Töltsön ki további információkat, amelyek gyorsabban kapcsolatba léphetnek veled

Adatvédelmi nyilatkozat: Az Ön adatvédelme nagyon fontos számunkra. Cégünk megígéri, hogy nem tesz közzé személyes adatait semmilyen kitettségnek az explicit engedélyekkel.