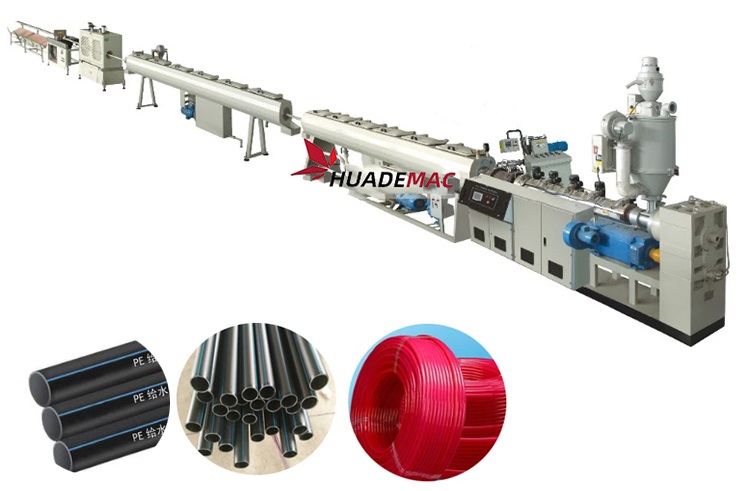

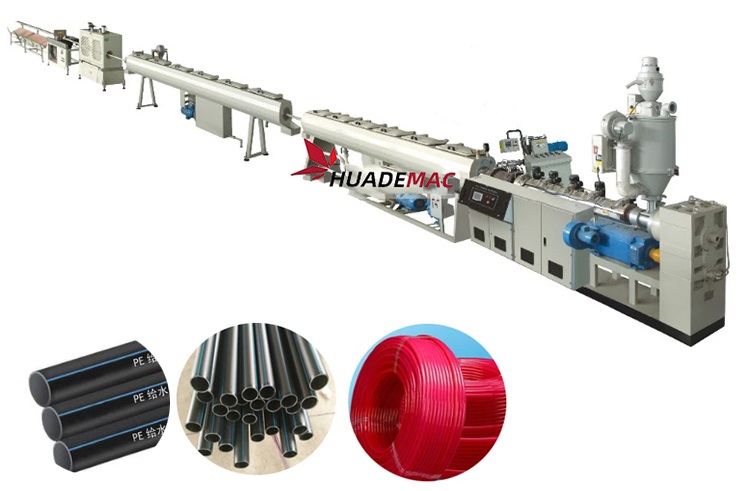

HDPE Pe Pipe Production Line making machine

Function of production line

(1) raw material mixing: it is to add PVC stabilizer, plasticizer, antioxidant and other auxiliary materials into the high-speed

mixer in proportion and process successively, heat up the materials to the set process temperature through self friction between materials and machinery, and then reduce the materials to 40-50 degrees through the cold mixer; in this way, it can be added into the hopper of the extruder.

(2) extruder part: This machine is equipped with a quantitative feeding device, so that the extrusion amount and feeding amount can match, to ensure the stable extrusion of products. Because of the characteristics of the conical screw, the feeding section has a large diameter, and the heat transfer area and shear speed of the material are relatively large, which is conducive to the plasticization of the material. The screw diameter of the metering section is small, reducing the heat transfer area and the shear speed of the melt, so that the melt can be extruded at a lower temperature. When the screw rotates in the barrel, the PVC mixture will be plasticized and pushed to the head of the machine, so as to achieve the purpose of compaction, melting, mixing and homogenization, and to achieve the purpose of exhaust and dehydration. The feeding device and screw drive device adopt frequency conversion speed regulation, which can realize synchronous speed regulation.

(3) extrusion die part: PVC after compaction, melting, mixing and homogenization. There are follow-up materials pushed to the die by screw. The extrusion die is the key component of pipe forming.

(4) the vacuum set water tank is used for the setting and cooling of pipes. The vacuum set water tank is equipped with a vacuum system and a water circulation system for setting and cooling. The stainless steel box is equipped with circulating water spray cooling. The vacuum set water tank is equipped with a front and back moving device and a left and right, high and low adjustment manual device.

(5) the traction machine is used to continuously and automatically lead the cooled and hardened pipes out of the machine head and adjust the speed by frequency conversion.

(6) cutting machine: after controlled by the travel switch according to the required length, the machine will cut automatically,turn over the rack in time, and carry out flow production. The cutting machine will complete the whole cutting process with the instruction of the switch signal of the permanent worker, keep synchronous with the pipe operation during the cutting process, and the cutting process will be driven by electric and pneumatic. The cutting machine is equipped with a dust absorption device to timely absorb the debris produced by cutting Out, and recycle.

(7) the turning operation of the turning frame is realized by the air cylinder through the control of the air circuit. The turning

is equipped with a limit device. When the pipe is cut by the cutting saw, the pipe will continue to be transported. After the

delay, the air cylinder will enter the work to realize the turning operation and achieve the unloading purpose. After unloading,it will reset automatically after a delay of several seconds and wait for the next cycle.

HDPE PE Pipe Production Line making machine photos

Extruder of PE HDPE pipe making machine

SJ65/33 PE/HDPE PIPE EXTRUDER MAIN TECHNICAL PARAMETERS

1. Single screw extruder: model sj65 / 33

2. Cylinder and screw material: 38CrMoAlA, after nitriding and grinding, the depth of nitriding layer is more than or equal to 0.6mm, which has sufficient strength, wear resistance and corrosion resistance;

3. Cylinder and screw structure: barrier screw, asymmetric slotted barrel design.

4. The gearbox is equipped with strong thrust bearing and high torque output; the gear is made of special alloy, with hard tooth surface and gear grinding process; high quality, high torque and high speed gearbox; low heat, low noise, long life and hard tooth surface reducer is equipped with external cooling system

5. Temperature control table of OMRON

6. ABB or Siemens brand inverter

7. Schneider or Siemens AC contactor

8. Siemens Bede motor

9. Diameter of screw: Φ 65mm

10. Length diameter ratio of screw: 33:1

11. Driving motor power: 55kW high speed screw

12. Gearbox: high torque, low noise, hard tooth surface grinding reducer is equipped with external cooling circulation system

13. Heating power of barrel: 5 × 4.5kw (cast aluminum heating ring)

14. Cooling power : 5 × 0.25kw forced air cooling

15. The output is 100-200kg / h

![W[}DHI9_L9]1`KGWHB5{EJV W[}DHI9_L9]1`KGWHB5{EJV](//bsg-i.nbxc.com/product/ea/bf/63/c38dc451f9ff3f537619d79401.png)

Packaging of PE water supply pipe making machine

Exhibition of water supply pipe making machine

![W[}DHI9_L9]1`KGWHB5{EJV W[}DHI9_L9]1`KGWHB5{EJV](http://bsg-i.nbxc.com/product/ea/bf/63/c38dc451f9ff3f537619d79401.png)