Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: HD1000

Brand: huade

Place Of Origin: China

Status: New

Plastic Type: Bopp, Pe, Pp/Pe

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Core Components: Bearing

Warranty Period: 1 Year

Core Selling Point: Energy Saving, Long Service Life

Applicable Industry: Building Material Shops, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Philippines, Malaysia, Morocco, Chile

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, United States, Saudi Arabia, Mexico

Packaging: film wrap and fixed in container

Productivity: 300-350kg

Transportation: Ocean

Place of Origin: china

Supply Ability: 10set per month

Certificate: CE

HS Code: 84778000

Port: Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

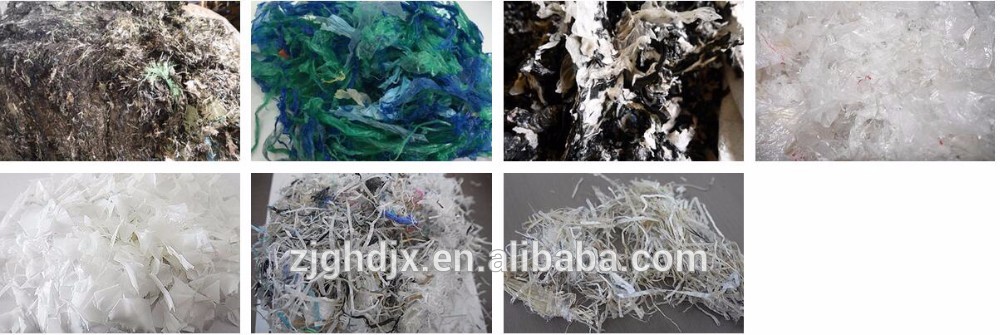

Materials before process

Materials after process

More products, pls click here.

Product Features

1. The latest solutions for film washing line

If you would like to produce the high quality and validity of pellets, you beware "Squeezing process must be prior to pelletizing process". After plastic recycled film materials are washed, the moisture is usually retain over 30%. Therefore, our superior design team specially developed a squeezer to meet customers' needs. Through this machine, water and volume of the materials can be squeezed to increase the quality of the pellets and the efficiency of the extruders.

2. High Productivity

Through our dedicated screw design, washed materials can be squeezed to dehydrate water of films or fluffy stuff. The recycled materials you feed are squeezed to become flakes or lumps .The moisture they contain will be lowered down to 1-3%. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. Its output can amount to 700~1000kg/hr per hour and the degradation of the pellets will be highly decreased. Furthermore, you don't need to increase heating rate. The quality and validity of the pellets and the efficiency of the extruder will be improved with the increased capacity.

3.Always your best choice

Our screw squeezer can help you SAVE cost, SAVE energy, SAVE time, PROTECT environment, and INCREASE productivity as well as efficiency. It is definite your best choice! You NEVER miss it.

Please select Your Model

Note:All of our products can be customized according to customer requirements.

We have 250-350kg/h, 450-600kg/h, 700-1000kg/h

Product Categories : Plastic Recycling Granulating Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.