Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SJZ65

Product Type: PVC Profile

Screw: Double-Screw

Automation: Automatic

Computerized: Non-Computerized

Certification: SGS

Customized: Customized

Packaging: film wrap and fixed in container

Transportation: Ocean

Port: Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

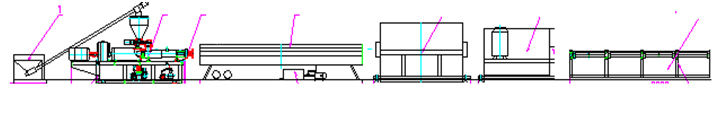

PVC Artificial Marble Profile Extrusion Line

PVC Imitation Marble Sheet Producing Machinery/Stone Profile Machinery

PVC Marble Profile Skirting and Siding Board Making Machine

Source Factory PVC Imitation Marble Profile Production Line

PVC marble profile,photo frame,skirting line, floor board ceiling corner etc for indoor decoration.

Advantage of PVC marble profiles:

With a lot of colors and color consistency and Large surface application.

Never seeped oil. Waterproof, anticorrosive, moth-proofing.

Natural & Attractive appearance and nice heat and sound insulation

No radiation, Non-toxic and eco-friendly features

Easy installation,

Machine Features:

Energy savings

Less space needed

Simple logistic management

Substantial cost savings (investment, management …)

Formulations adjustable in-line

Maintain a proprietary in-house manufacturing process

Technical Parameter:

| Screw Diameter | Capacity | Capacity | Extruder Power | Line Length |

| SJZ 51 | 51/105 | 80-100KG/H | 18.5kw | 10-16m |

| SJZ 55 | 55/120 | 100-180kg/h | 22-30kw | 12-20m |

| SJZ65 | 65/132mm | 150-200kg/h | 37kw | 15-25m |

| SJZ80 | 80/156mm | 200-300kg/h | 55kw-75kw | 15-30m |

The PVC artificial marble profile making machine equip with the conical twin screw extruder , converter control system , OMRON temperature control unit , it has wide control range , accuracy temperature control and easy to operate , the auxiliary equipment consist of vacuum calibration mould & platform, hauling off machine, hot stamping machine , cutting machine, stack machine ,etc.

Twin screw extruder

World famous brand electrical component: Siemens, Schneider, ABB etc;

High torque gearbox with adopts NSK/SKF bearing;

Siemens original motor achieved global after service;

Bimetallic screw and barrel;

Simple PID automatic temperature control system

Die head

Material 3Cr17, it includes the die head parts, vacuum calibrator parts, water cooling tank parts

PVC marbles profile production process : the screw feeder feed the raw materials to the mixer unit , after mix enough and the temperature reach the set temperature , the hot mixed raw materials will discharge into the cooling mixer automatically , then the spring feeder feed the mixed raw materials into the twin screw extruder , after plasticizing , extrusion and calibration , the profile will come out from the mould and follow into the cooling equipment , via the synchronous haul off machine , the profile enter the cutter , the cutter equip with the meter counter , it can cut different size according to the set length automatically .

Vacuum calibration table

Adopts powerful turbo cooling system, easy to achieve satisfactory cooling effect.

2 caterpillar haul off & Cutter

Cutting machine speed is synchronized with hauling speed.

Stacking

Profile surface treatment device (hot stamping machine )

PVC artificial marble profile auxiliary equipment:

Product Categories : Plastic Profile Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.