Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 20-63mm

Application: Pipe

Processing Plastic Type: Pe, Pp, Ppr, Hdpe/Pp, Pe/Pp

Status: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 33:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Energy Saving

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Garment Shops, Machinery Repair Shops, Food &Amp; Beverage Factory, Printing Shops, Food &Amp; Beverage Shops, Advertising Company

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Pump, Gearbox, Screw

Packaging: Wooden Pallet

Transportation: Ocean

Port: Shanghai Port

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Plastic PPR Pipe Making Machine

Characteristics of Plastic PPR Pipe Making Machine:

1. This machine is mainly used for pipe production with PPR resin as raw material. 2. The design of slotted feeder barrel and barrier screw can improve the plasticizing effect. 3. High extrusion rate, low melt temperature and uniform temperature. 4. Barrier type two pole mixing, i.e. special screw for day, slotting barrel. 5. Equipped with a new type of secondary split die, with the characteristics of low temperature and low pressure extrusion: water film sizing sleeve, to ensure the high-speed production of pipes. 6. The production line is controlled by PLC, and PPR cold and hot water Pipe Production Line manufacturer has good man-machine interface. 7. The marking line can be selected to extrude to produce the pipe with color mark. The production line can produce PE pipe by changing mould. 8. Random polypropylene production line is mainly used to produce pipe production line with PP-R resin as raw material, and also suitable for pipe production with PP, Pb and PE resin as raw materials. SJ-65 / 33 is used as extruder, equipped with corresponding mould, cooling device and traction device, which is used for continuous and efficient extrusion of pipes. It has the characteristics of stable quality and convenient operation.

Plastic PPR Pipe Making Machine process

Drying of raw materials→ Extrusion molding → Vacuum sizing → Spray cooling → Haul-off → Fixed length cutting → Pipe filling and unloading

Plastic PPR Pipe Making Machine photos

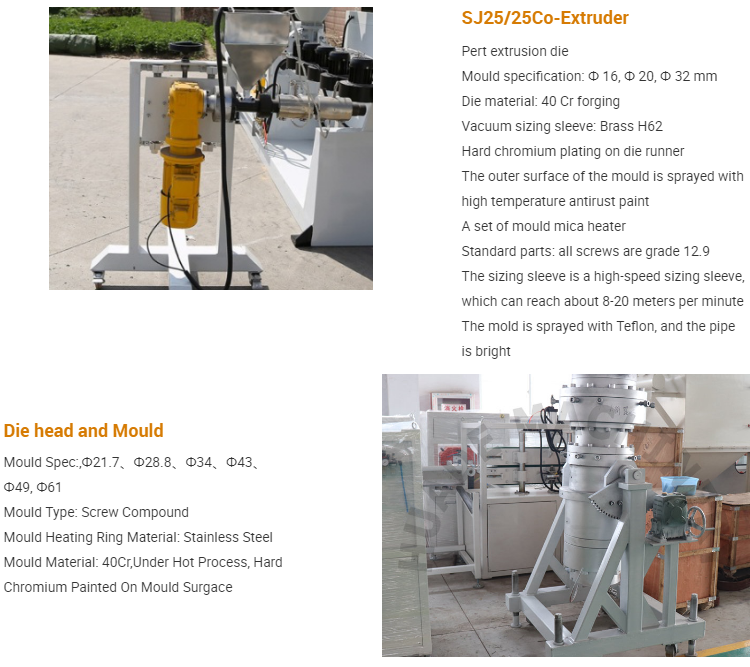

SJ65/33 extruder of PPR 4 layer co-extrusion line

1. Single screw extruder: model SJ65 / 33

2. Cylinder and screw material: 38CrMoAlA,

3. Cylinder and screw structure: barrier screw, asymmetric slotted barrel design.

4. The gearbox is equipped with strong thrust bearing and high torque output; the gear is made of special alloy, with hard tooth surface and gear grinding process;

5. Temperature control table of OMRON

6. ABB or Siemens brand inverter

7. Schneider or Siemens AC contactor

8. Siemens Bede motor

9. Diameter of screw: Φ 65mm

10. Length diameter ratio of screw: 33:1

11. Driving motor power: 55kW high speed screw

12. Gearbox: high torque, low noise, hard tooth surface grinding reducer is equipped with external cooling circulation system

![%X7]3_3)P1F`Z8)H{P$IZ46 %X7]3_3)P1F`Z8)H{P$IZ46](http://bsg-i.nbxc.com/product/57/e5/10/3661ccf114bb06b4874e588f2c.png)

![26}0CO[_{GNS}`PP]SIBIIY 26}0CO[_{GNS}`PP]SIBIIY](http://bsg-i.nbxc.com/product/22/8d/4d/e5a4b9ed2d7fee3d7f08c337fb.png)

![{]LTKZG95X7S6RQ%DXL%WK2 {]LTKZG95X7S6RQ%DXL%WK2](http://bsg-i.nbxc.com/product/cb/b5/15/da52f89af72edfdc4caceac211.png)

![3W]E40_WY3WCSFWB%U0%~]L 3W]E40_WY3WCSFWB%U0%~]L](http://bsg-i.nbxc.com/product/03/44/5d/d88d430f785326d5d986008ea0.png)

Packaging of Plastic PPR Pipe Making Machine

Exhibition of Plastic PPR Pipe Making Machine

Product Categories : PPR PPRC Pipe Extrusion Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.