Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 63-200mm

Product Type: PVC Pipe

Screw No.: Double-screw

Automation: Automatic

Computerized: Computerized

Certification: ISO9001:2008

Customized: Customized

Condition: New

Material: PVC

Motor: Siemens

Screw: Twin-Screw

Inverter: ABB Brand

Name: Extrusion Machine

Packaging: Wooden Pallet

Transportation: Ocean

Port: Shanghai Port

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

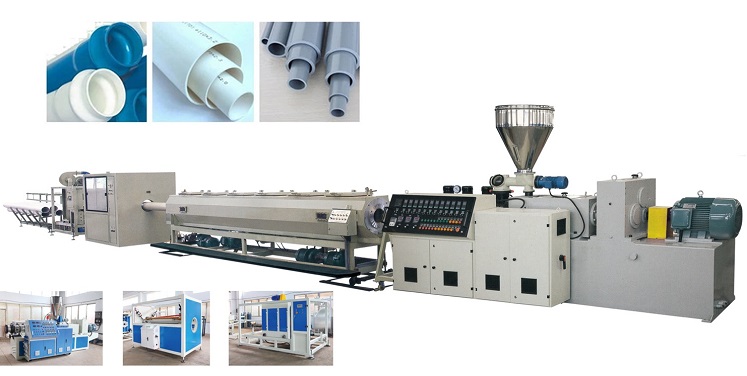

One cavity PVC pipe extrusion line description

This set is composed of conical twin-screw extrude, Vacuum Calibration Tank, Haul-off Machine, cutter, stacker etc.

The screw extruder and traction machine adopt imported AC frequency control device.

The vacuum pump and traction motor both adopt advanced products.

The haul-off machine has many models, such as two-claw, three-claw, four-claw, six-claw etc.

It may choose visual blade or cutting type.The unit is of reliable performance and high production efficiency.

Our machine can produce the PVC pipe with diameter from 16mm to 800mm

Pipe diameter range(mm): 63-200mm

Extruder Motor powder(kw): 37kw

Output(kg/h):80-200(kg/h)

Total length: 25m

Wall thickness: by required

Processing flow of pvc pipe extrusion line:

PVC powder + additive → spring feeding → twin screw extruder → mould and calibrator→ vacuum forming machine → haul off machine → cutting machine → discharging rack

One cavity PVC pipe extrusion line photos

Extruder

According to the direction of material flow and the angle of screw center line, the extruder head can be divided into right angle head and oblique angle head.

Screw extruder relies on the pressure and shear force produced by screw rotation, which can make the material fully plasticized and evenly mixed, and then molded by die.

Die-head

Main materials of Body, bin and push: 40Cr

Calibrator: copper or stainless steel, water-ring type

Vacuum Sizing Box

Tank materials: 304 S. S.Materials

Water temperature and level controlling technology;

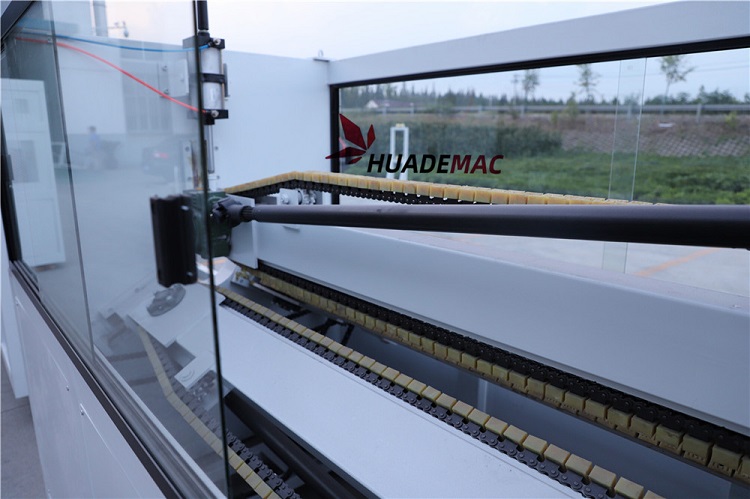

Haul-off Unit

Driving motor power: 1.5kw * 3 sets

The maximum traction speed: 0.5-20m/min

The maximum traction force: 3000n

Clamping mode: Pneumatic

Cutter

Cutting method: Manual/Automatic

Cutting length: Measured by encoder or travelling switch

Up & Down Clamping: Pneumatic

Stacker

Stainless steel 304 as touching material

Discharge driving by air cylinder

Packaging

Exhibition

Product Categories : PVC Large Diameter Pipe Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.