Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 110-250

Brand: HUADE

Application: Pipe

Processing Plastic Type: Pvc

Status: New

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 132:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, United States, Brazil, Argentina, Sri Lanka, Kazakhstan

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Multifunctional

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Mexico, Morocco, Colombia

Applicable Industry: Building Material Shops, Manufacturing Plant, Food &Amp; Beverage Factory, Restaurant, Construction Works

Marketing Type: Hot Product 2019

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Bearing, Gear, Gearbox

Packaging: film wrapped and fixed in container

Productivity: 250

Transportation: Ocean

Place of Origin: CHINA

Supply Ability: 10

Certificate: CE

HS Code: 84778000

Port: Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Diameter Range (mm): 110 140 160 200 250mm wall thickness by request

Main Extruder Motor Power: 37kw

Line Space Occupation: 38mx4mx3m

Capacity: 200-250kg/h

Product Description

Application of PVC,UPVC Wall Pipe extrusion production line / UPVC pipe making machine:

Applied for manufacture of caliber PVC,UPVC water supply and drain pipes,electric conduit pipe, etc

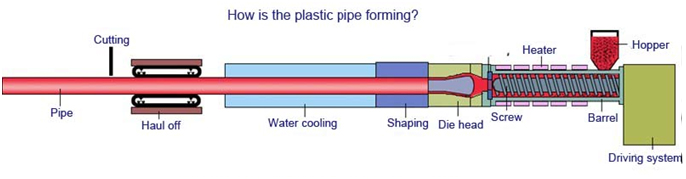

Components Of A typical PVC Pipe Production Line

UPVC pipe production line is comprised of a number of machines as following:

Extruder Machine: The starting point and heart of every pipe production line, the extruder machine heats and melts virgin or recycled plastic materials,delivering it to the pipe extrusion die head.

Pipe extrusion die head: Forms the extruded plastic into the desired pipe profile.

Vacuum & Cooling Tank: Cooling of the produced pipe, at a precise temperature range in order to cool and stabilize the pipe in the desired shape.

Haul off/puller: Pulling of the pipe after cooling, ensuring consistent pipe thickness and dimensional stability.

Pipe cutter: Positioned after the haul off machine, for cutting of the extruded pipe in the desired length during production.

Stacking Unit:put after cutter for straight pipe laying for late transportation and use.

Belling machine comes at the end,belling is the process of heating the end of a PVC tube and expanding its diameter using a mold.The enlarged end is called a bell, socket or the male-end.

Working flow of PVC,UPVC Wall Pipe extrusion production line / UPVC pipe making machine

Details Images

Product Categories : PVC Sewer Pipe Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.