Declarație de confidențialitate: Confidențialitatea dvs. este foarte importantă pentru noi. Compania noastră promite să nu vă dezvăluie informațiile personale pentru nicio expansiune cu permisiunile dvs. explicite.

Numarul modelului.: SJSZ92/188

cerere: Pelletizing

Processing Plastic Type: Pvc

stare: New

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): Other

Screw Length To Diameter Ratio: 188:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Out-of-warranty Service: Video Technical Support, Spare Parts, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Manufacturing Plant

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Gear

ambalare: plaster film wrapped

Transport: Ocean

Abilitatea de alimentare: 5sets per month

Port: taicang ,shanghai ,ningbo

Tipul de plată: T/T,L/C

Incoterm: FOB,CFR,CIF

UPVC PVC plastic hot cut pelletizing machine

PVC UPVC plastic pelletizing granulating machine line for sale

Description:

This PVC plastic pelletizing machine is design specializes for recycling the recycled washed plastic PVC plastic flakes/scraps, such as PVC pipe flakes/scraps, PVC sheet flakes/scraps etc.

After processing techniques such as feeding, heating, melt, cutting, cooling etc., the final products are PVC plastic pellets/granules that can be to produce new PVC plastic products.

Features

The screw is made of high tool steel 38 CrMoALA, Special screw combination Euro-style rectangle barrel, reflux refrigeration channel optimized and disposed, which makes temperature difference in D areas smaller.

Innovated design of heater-tightened style insures high efficiency of heat transfer and high longevity of heater.

Working Flow of PVC plastic pelletizing Recycling machine:

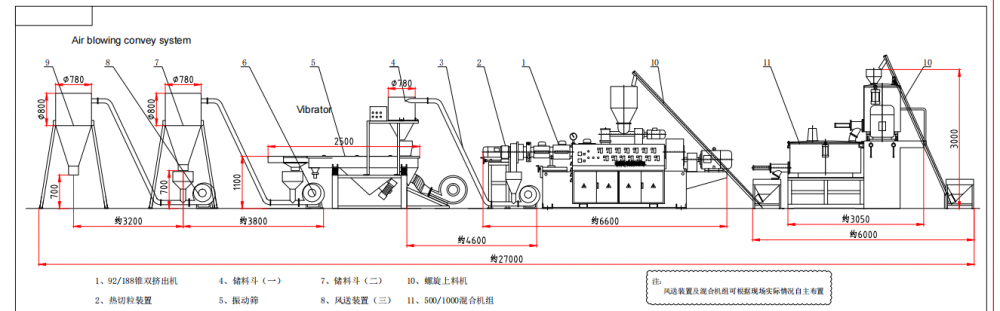

Screw feeder → Conical twin extruder → Cutting → Blower → Storage hopper → Blower → Storage hopper → Electric control panel

Screw feeder: the first step of the pelletizing recycling machine, Pvc plastic flakes/scraps conveyed into the hopper through screw, the screw connect sensor to detect the material in hopper, once the flakes are full in hopper, the screw will stop; and once empty, the screw feeder will begin working.

Extruder: to plasticization and degassing, a specialized single screw extruder applied to melt the pre-compacted material. The plastic scraps will well melted, plasticized in the first stage extruder, and the plastic will be extrude by the second stage extruder. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

Cutting pelletizing: supplied with speed steel and hard alloy steel cutting blades for reliable performance. Compact structure allows less maintenance.

Blower and hopper: to cooling the PVC pellets and storage the pellets.

Categorii de produse : Plastic Recycling Granulating Line

Site-ul mobil

Declarație de confidențialitate: Confidențialitatea dvs. este foarte importantă pentru noi. Compania noastră promite să nu vă dezvăluie informațiile personale pentru nicio expansiune cu permisiunile dvs. explicite.

Completați mai multe informații, astfel încât să poată lua legătura cu tine mai repede

Declarație de confidențialitate: Confidențialitatea dvs. este foarte importantă pentru noi. Compania noastră promite să nu vă dezvăluie informațiile personale pentru nicio expansiune cu permisiunile dvs. explicite.