Vyhlásenie o ochrane osobných údajov: Vaše súkromie je pre nás veľmi dôležité. Naša spoločnosť sľubuje, že vaše osobné informácie zverejní akýmkoľvek expanziou bez vašich výslovných povolení.

Model č.: 16-32mm

prihláška: Pipe

Processing Plastic Type: Pvc

Postavenie: New

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 132:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: High-Accuracy

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Hotels, Machinery Repair Shops, Retail, Construction Works

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Gearbox, Screw

obal: Wooden Pallet

preprava: Ocean

prístav: Shanghai Port

Typ platby: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

PVC four cavity pipe extruding making machine

Machine features

one mould 4 cavity pvc pipe extruder line can be used to prodcuce 4 pipes at one time to improve the production efficiency. machine capacity can easily reach 5.5-6.5t per day. Producing speed can reach 8-10m/min when doing pipe diameter 16mm.

|

suitable pipe diameter

|

16-32mm

|

|

traction machine

|

4 drawer fluctuation traction (caterpillar)

|

|

traction speed

|

1-10m/min

|

|

traction force

|

6000

|

Process Flow:

Screw Loader for Mixer→ Mixer unit→ Screw Loader for Extruder→ Conical twin screw extruder → Mould → Vacuum Calibration Cooling Tank → Haul-off and cutting unit → Belling machine/ Stacker → Final Product Inspecting & Packing

CHARACTERISTICS and APPLICATIONS

Four station haul-off:up-down two caterpillar tracking

Drawing speed:1-10m/min

Drawing forth:6000N

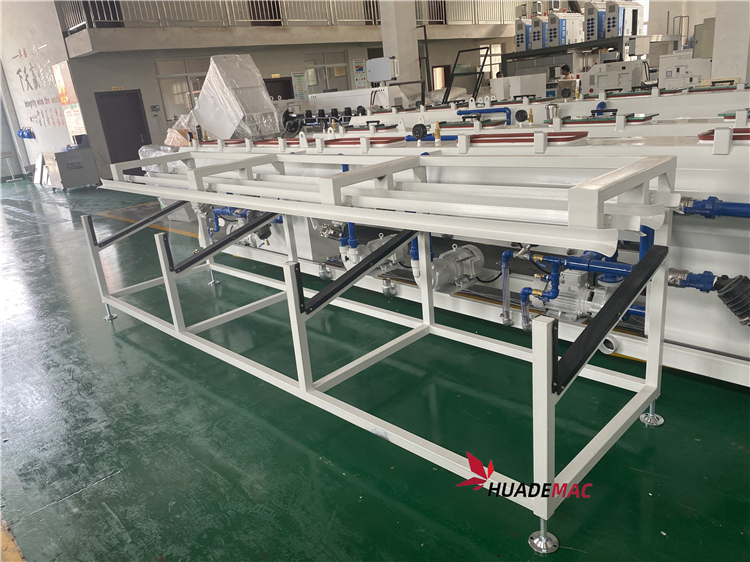

PVC four cavity pipe extruding making machine photos

Extruder

Extruder is one of the types of plastic machinery, originated in the 18th century.

According to the direction of material flow and the angle of screw center line, the extruder head can be divided into right angle head and oblique angle head.

Screw extruder relies on the pressure and shear force produced by screw rotation, which can make the material fully plasticized and evenly mixed, and then molded by die.

Die-head

Vacuum Calibrating

Tank materials: 304 S. S.Materials

Water temperature and level controlling technology;

Haul-off & Cutter

Cutting method: Manual/Automatic

Cutting length: Measured by encoder or travelling switch

Up & Down Clamping: Pneumatic

Frame structure: beautiful appearance, safe operation

Stacker

The height is adjustable

Stainless steel 304 as touching material

Discharge driving by air cylinder

Packaging of PVC four cavity pipe extruding making machine

Exhibition of PVC four cavity pipe extruding making machine

Kategórie produktov : PVC Conduit Pipe Production Line

Mobilné stránky

Vyhlásenie o ochrane osobných údajov: Vaše súkromie je pre nás veľmi dôležité. Naša spoločnosť sľubuje, že vaše osobné informácie zverejní akýmkoľvek expanziou bez vašich výslovných povolení.

Vyplňte viac informácií, ktoré sa s vami môžu rýchlejšie spojiť

Vyhlásenie o ochrane osobných údajov: Vaše súkromie je pre nás veľmi dôležité. Naša spoločnosť sľubuje, že vaše osobné informácie zverejní akýmkoľvek expanziou bez vašich výslovných povolení.