Bayaanka Asturnaanta

Tusaale ahaan.: 2000kg/h

Codsiga: Plates, Pelletizing

Processing Plastic Type: Pet

Xaaladda: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 180

Screw Length To Diameter Ratio: Other

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Garment Shops, Machinery Repair Shops, Retail, Food Shop, Food &Amp; Beverage Shops, Other

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Gearbox, Screw

Baakadaha: Wooden Pallet

Gaadiidka: Ocean

Port: Shanghai Port

Nooca Bixinta: L/C,T/T,D/P

Madadaalo: FOB,CFR,CIF,EXW

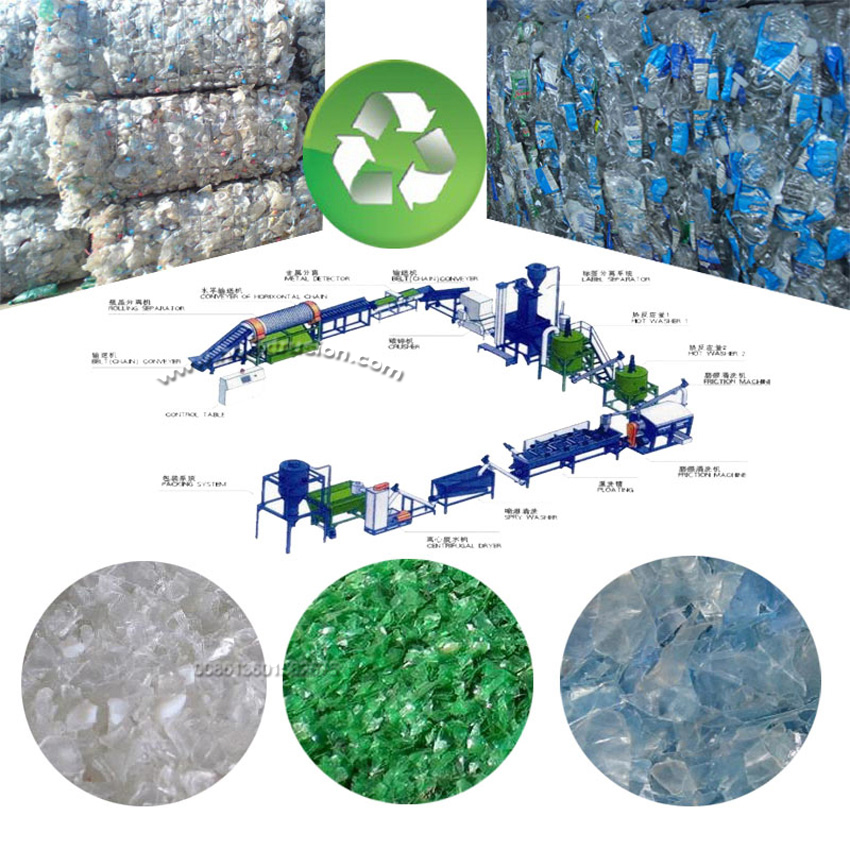

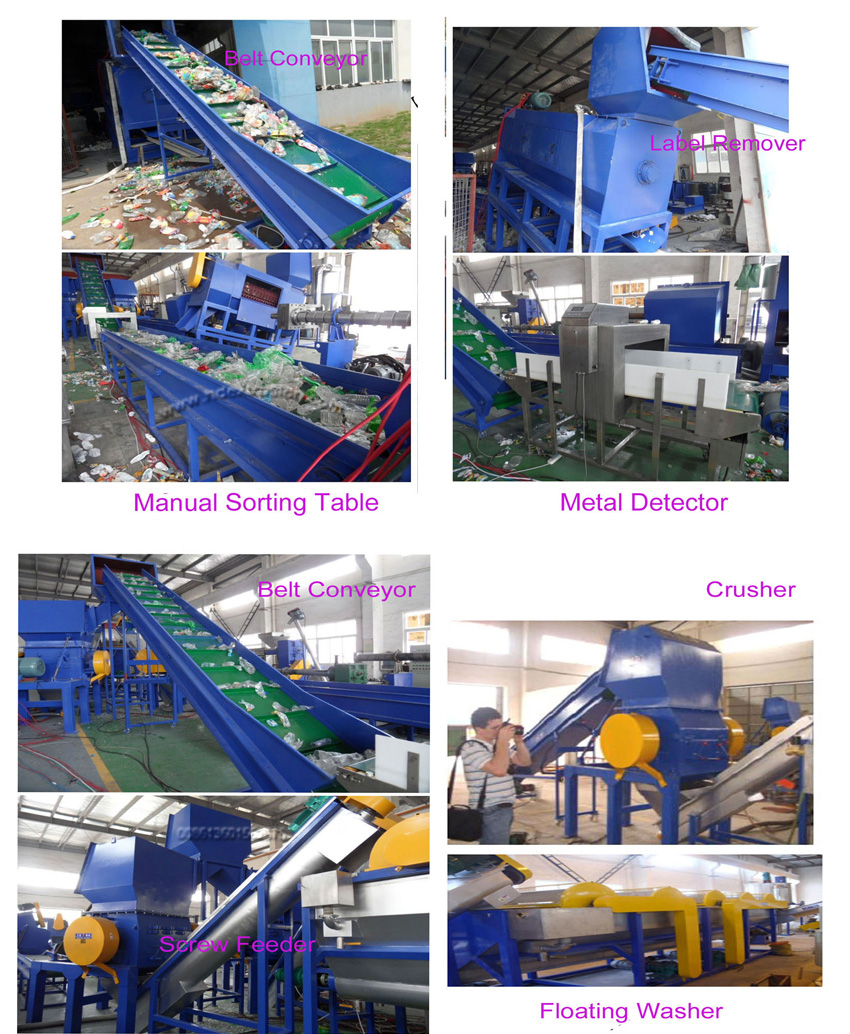

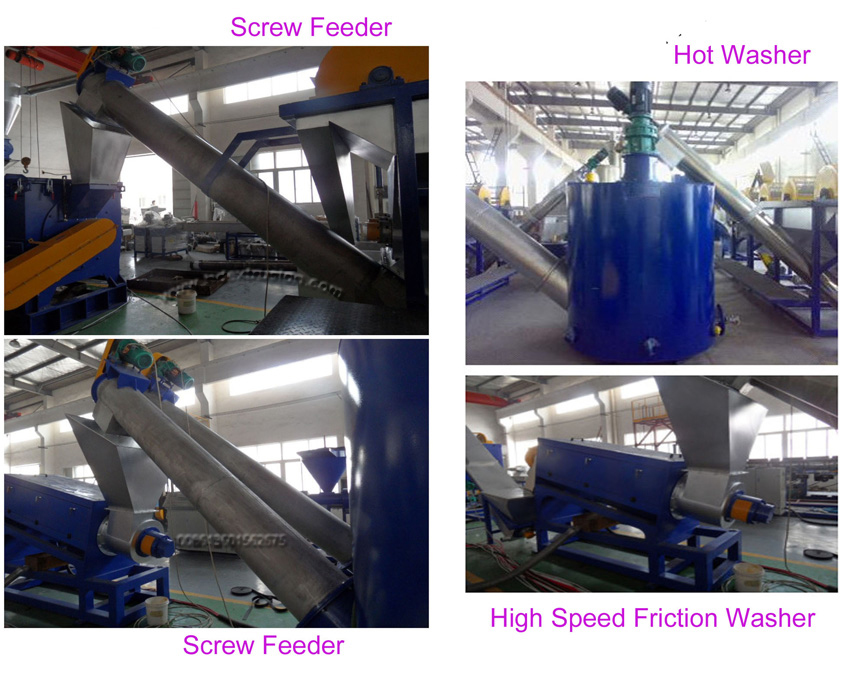

Hot washing PET flakes recycling line

Advantages:

1. Final products has good quality. When process PP PE film bags, final products humidity below 2%.

2. The machine with high efficiency, working stable, large capacity etc.

3. Parts which contact material use SUS304, thickness more than 3mm, ensure long service life time.

4. World famous brand components applied on the production line

5. The whole production line with CE certification, ISO9001 certification .

Description:

Technical dates:

|

Material |

Model |

Capacity |

Installed power |

Water supply |

Manpower |

Area required |

|

PET bottle |

MT series |

500kg/h |

130+60kw |

2-3m3/h |

6-7 person |

55*5*3.5(L*W*H) |

|

1000kg/h |

250+120kw |

4-5m3/h |

7-8 person |

65*6*3.5(L*W*H) |

||

|

2000kg/h |

350+120kw |

6-8m3/h |

8-10person |

75*6*4.5(L*W*H) |

||

|

3000kg/h |

500kw |

8-10m3/h |

10-12person |

90*6*5.5(L*W*H) |

Our Main Products

Packaging

Zhangjiagang Huade Machinery

Certification

Qaybaha alaabta : Plastic Recycling Washing Line

Site Mobile

Bayaanka Asturnaanta

Buuxi macluumaad dheeri ah si markaa si dhakhso leh ula xiriiri karto

Bayaanka Asturnaanta