Bayaanka Asturnaanta

Tusaale ahaan.: 20-63mm

Codsiga: Pipe

Processing Plastic Type: Pe, Pp, Ppr, Hdpe/Pp, Pe/Pp

Xaaladda: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 33:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Energy Saving

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Garment Shops, Machinery Repair Shops, Food &Amp; Beverage Factory, Printing Shops, Food &Amp; Beverage Shops, Advertising Company

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Pump, Gearbox, Screw

Baakadaha: Wooden Pallet

Gaadiidka: Ocean

Port: Shanghai Port

Nooca Bixinta: L/C,T/T

Madadaalo: FOB,CFR,CIF,EXW

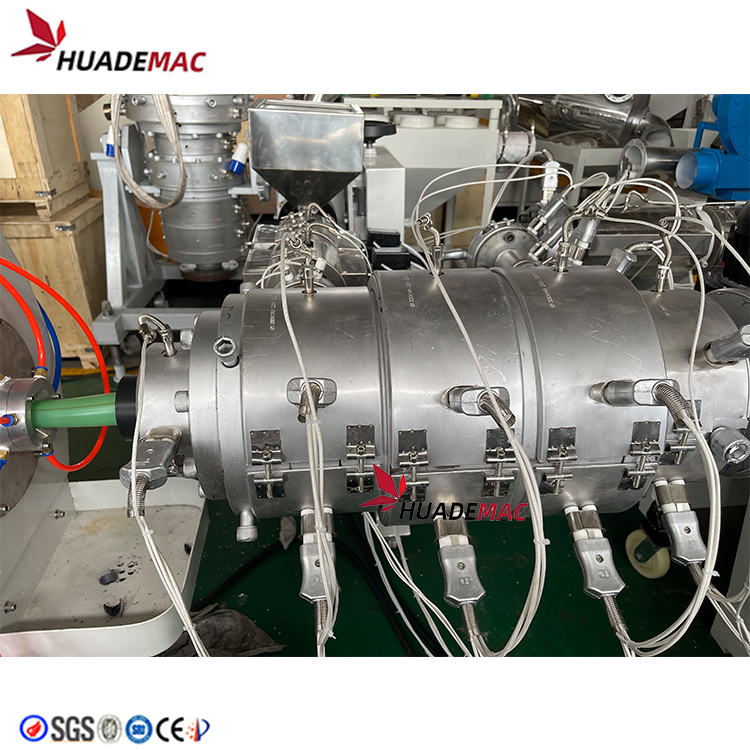

20-63mm PPR 3-layers pipe production line

20-63mm PPR 3-layers pipe production line:

PPR hot cold water supply drainage pipe machine of three-layer co extrusion PPR pipe is a new product developed by our company by introducing and absorbing foreign advanced technology. Its screw, die and other key components are specially designed according to the characteristics of pp-r. Through the three-layer coextrusion technology, the spiral three-layer co extrusion die with special design is adopted to ensure the uniform thickness of three layers and the thickness of each layer can be adjusted arbitrarily. Spiral split die can be equipped with static mixing system. The material layers are fully overlapped with each other. Compared with the traditional support die head, the internal pressure is more uniform. In the form of ABA, the glass fiber in the middle reinforcement layer is arranged regularly, and organically melts with the inner and outer PPR layers to form a whole, which significantly overcomes the overhanging phenomenon of the pure PPR pipe in surface installation, and reduces the linear expansion coefficient of the pipe.

PPR Pipe Production Line / Extrusion Machine/ Extruder process

Drying of raw materials→ Extrusion molding → Vacuum sizing → Spray cooling → Haul-off → Fixed length cutting → Pipe filling and unloading

PPR Pipe Production Line / Extrusion Machine/ Extruder photos

Exhibition of 20-63mm PPR 3-layers pipe production line

Qaybaha alaabta : PPR PPRC Pipe Extrusion Line

Site Mobile

Bayaanka Asturnaanta

Buuxi macluumaad dheeri ah si markaa si dhakhso leh ula xiriiri karto

Bayaanka Asturnaanta