conversion control

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: 110-200

ʻO Brand: huade

Ka hoʻohana: Pipe

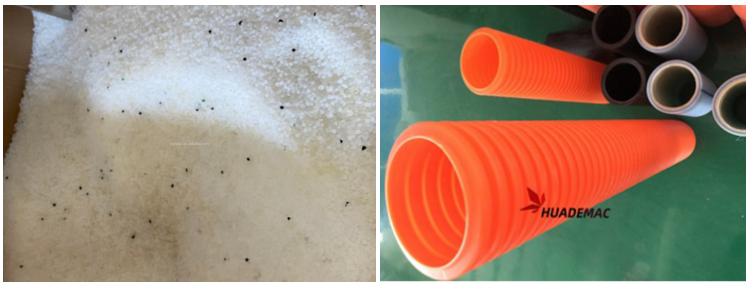

Processing Plastic Type: Pe, Pp

Kūlana: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 75

Screw Length To Diameter Ratio: 33:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Pakistan, Argentina, Algeria

Place Of Origin: China

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Philippines, Saudi Arabia, Russia, Australia

Applicable Industry: Manufacturing Plant

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Gear

Packaging: film wrap and fixed in container

'Ohanahana: 300-450kg/h

Nā kaʻa: Ocean

Ka hoʻolakoʻana i ka pono: 10set per month

Palapala: CE

HS Code: 8477800

ʻO Port: Shanghai

ʻO keʻano o ka uku: L/C,T/T

ʻO Incoterm: FOB,CFR

Extruder model: SJ75/30 &SJ90/30

Forming moulds: 42 pairs of modules =84 pieces

Size:110-140-160-180-200mm

capacity:300-500kg/h

Line occupation:15mX4mX3m

Single Screw Extruder

Driven motor: It is main part of single screw extruder. We'd better choose good brand AC type driven motor matching with inverter

controll for saving power running cost.

Gear recuder box: It is used for connecting motor and for reducing rotating speed of screw through size and teeth of gear changing

in the gear box.

Screw and barrel: It is most important part of single screw extruder. Design of single screw is becoming to special and customzied

now due to many different kind plasic materials are using. The surface of screw should be paint double alloy for anti-wear.

Casting aluminum heater: It is used for heating barrel and screw which ensure mixed PVC/PE/PP resin material can be plasticizing and melting under the suitable temperature.

Cooling blower : It is used for cooling barrel and screw. if temperature of screw and barrel will be excess setting

temperature,cooling blowers start to work for cooling barrel which avoid PVC/PE/PP material resolved in the inside of barrel.

Hopper : It is used for keep the mixed PVC/PE/PP resin material in the silo and make sure material can be into barrel

continuously. It is like a material transport station.

Control Cabinet: It is used for control whole cornic double screw extruder running by switchs or PLC programes according to different circuits control required.

Die head and Mould

1 Material: 40Cr

2. Inner Diameter of corrubated: 7mm

3 Die head stainless steel heating ring, one heating zone

4 42 pairs of modules = 84 pieces

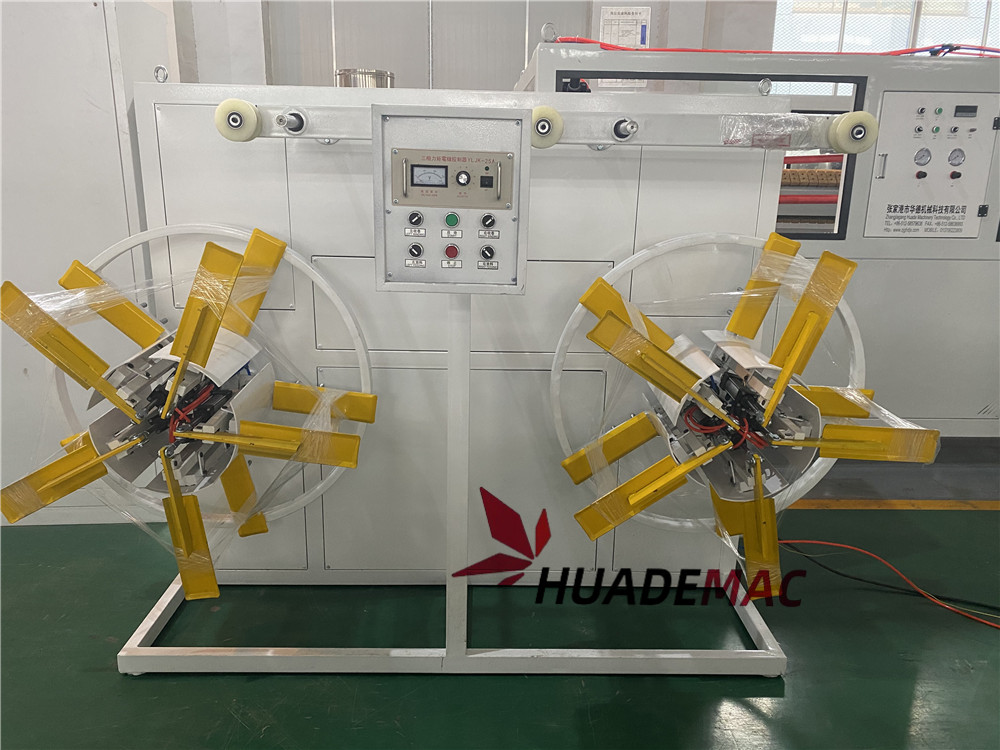

1. Winding inner diameter: 350mm-900mm, adjustable;

10. Take up pneumatic setting, automatic wire arrangement;

Packing & Delivery of PP PE single corrugated Pipe Extrusion Line

Nā huahana huahana : Double Wall Corrugated Pipe Production Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.