Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: HD500

Packaging: film wrap and fixed in container

Nā kaʻa: Ocean

ʻO Port: Shanghai

ʻO keʻano o ka uku: L/C,T/T

ʻO Incoterm: FOB,CFR,CIF

PP Woven Bag Plastic Squeezing Granulating Machine PP Woven Bag Plastic Squeezing Granulating Machine

Recycled PP PE Film Squeezer Waste Plastic Film Squeezing Machine in Africa

Waste PP PE Film Bag Recycling Plastic Granule/Pellet Squeezer Dryer Making/Squeezing/Dewatering/Pelletizing/Granulating Machine by Chinese Factory

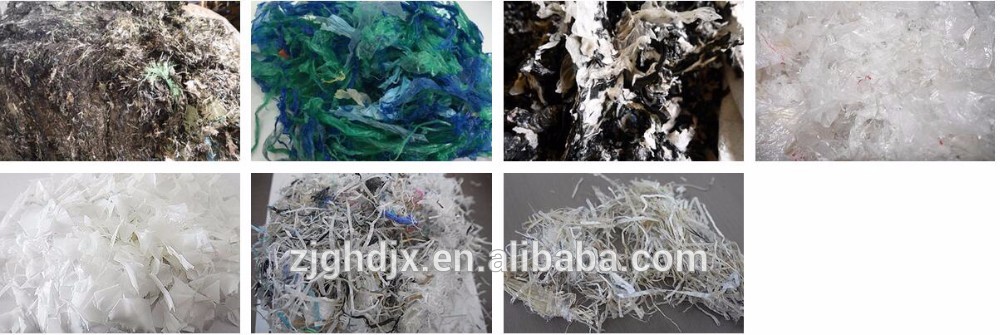

Materials before process

Materials after process

Squeeze Machine Features

1. The latest solutions for film washing line

If you would like to produce the high quality and validity of pellets, you beware "Squeezing process must be prior to pelletizing process". After plastic recycled film materials are washed, the moisture is usually retain over 30%. Therefore, our superior design team specially developed a squeezer to meet customers' needs. Through this machine, water and volume of the materials can be squeezed to increase the quality of the pellets and the efficiency of the extruders.

2. High Productivity

Through our dedicated screw design, washed materials can be squeezed to dehydrate water of films or fluffy stuff. The recycled materials you feed are squeezed to become flakes or lumps .The moisture they contain will be lowered down to 1-3%. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. Its output can amount to 700~1000kg/hr per hour and the degradation of the pellets will be highly decreased. Furthermore, you don't need to increase heating rate. The quality and validity of the pellets and the efficiency of the extruder will be improved with the increased capacity.

3.Always your best choice

Our screw squeezer can help you SAVE cost, SAVE energy, SAVE time, PROTECT environment, and INCREASE productivity as well as efficiency. It is definite your best choice! You NEVER miss it.

Please select Your Model

Note:All of our products can be customized according to customer requirements.

We have 250-350kg/h, 450-600kg/h, 700-1000kg/h

Nā huahana huahana : Plastic Recycling Granulating Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.