Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: SJSZ80

Automation: Automatic

Computerized: Computerized

Certification: ISO9001:2008

Customized: Customized

Condition: New

Name: PVC Hot Cutting Pelletizing Line

Packaging: Wooden Pallet

Nā kaʻa: Ocean

ʻO Port: Shanghai Port

ʻO keʻano o ka uku: L/C,T/T,D/P

ʻO Incoterm: FOB,CFR,CIF,EXW

PVC hot cutting pelletizing machine

PVC granule extruding line is used to make granule from powder or waste material Add masterbath to make different color

1. This PVC granule extruding line is composed by a conical twin-screw extruder and the correspondingly pelletizing downstream equipment, it is suitable for the pelletizing of PVC,PE raw materials with wood powder or other additives.

2. The pellets produced by this machine is evenly, solid, elegance.

3. The pelletizing downstream equipment is the die face cutter, air transferring unit, vibration separating and cooling unit. This pelletizing downstream equipment has the features of high automation and high production efficiency.

4. The screw and barrel, made of 38CrMoAlA , are made through smithing, tempering, double aging, nitriding treatment. Differences from others: screw edge is tempered after rough finish with good harden ability, and double aging reduce efficiently stress. Meanwhile, through accurate processing, phases of the screw edges have small error. The barrel and screw have high universal property. The structure of screw is different to different materials.

Specifications:

1.Client reference

2.Capacity:100-1000kgh

3.Pellet size: Diameter: 2.5 to 3mm

The process flow of PVC pelletizing line as following:

Screw feeder →Side force feeder→ Extruding system1→High speed screen exchanging→Extruding system2 →High speed screen exchanger →water cooling bath→ air dryer→ pelletizer machine→ Silo

Our machine can recycle

PVC hot cutting pelletizing machine photos

Conical Twin Screw Extruder

Die Head and Hot Cut Pelletizer

Vibrating Sieve

Air cooling & Storage Bin.

Final Products

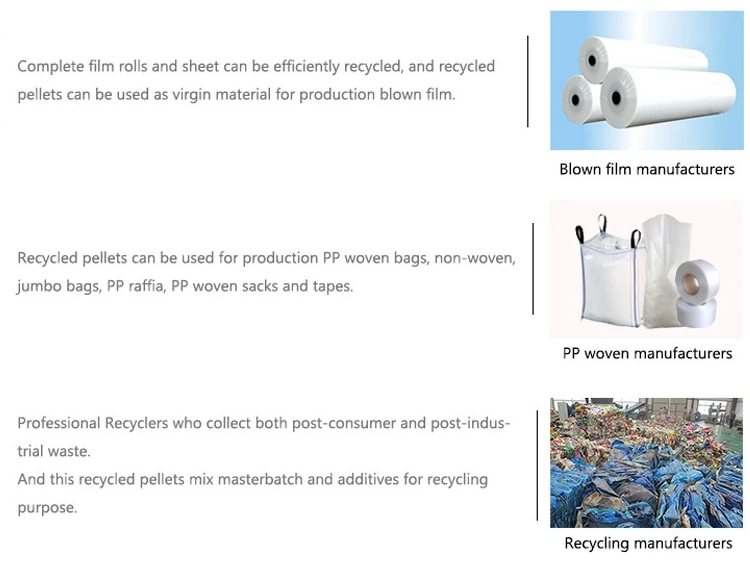

Recycled pellets application industry

Other Products

Zhangjiagang Huade Machinery

Packaging

Nā huahana huahana : Plastic Recycling Granulating Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.