Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: 320-420kg/h

Nā kaʻa: Ocean

ʻO Port: SHANGHAI

ʻO keʻano o ka uku: L/C,T/T,D/P

ʻO Incoterm: FOB

Wet Plastic Pelletizing Machine

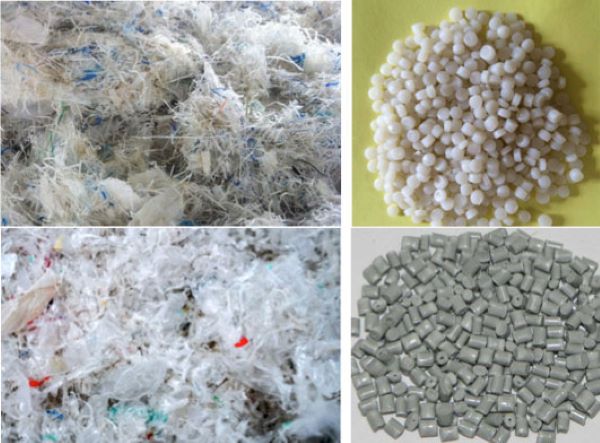

Our wet plastic pelletizing line is applied to recycle wet PP/PE film and woven bag etc.the raw material moisture can accept less than 15%.

The unit consists of loading device, extruder, die head, screen exchanger,pellet cutter,dewatering machine,vibrating sieve and silo. The machine capacity is available for 200-1000kg per hour.

Realted Machine:

PP PE film/woven bag

1.Loadig device

Function :

to load wet plastic film into the extruder

Function :

melt plastic and exhaust waste air with degassing zones.

double stage can get more good quality final granules

3.Screen Exchanger

Function :

Filter out impurities

4.Die Head

Function :

Form plasticized plastic to a particular shape for follow-up process.

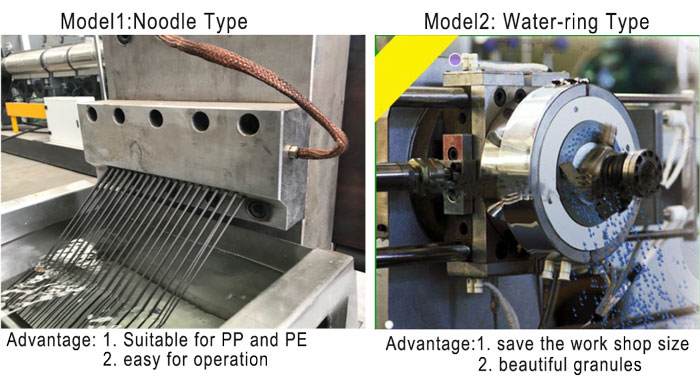

5.Pellet Cutting Machine

Water-ring type Cutting Device

Function :

Cut material out from die head to regular shape. Rinse to cool and shape up.

strand type cutting Device

Function:

Cut noodles to get regular plastic pellets.

6.Dewatering Machine

Water-ring type Cutting Device

Function :

Remove water by centrifugal force

7.Vibrating Sieve Air Blower And Silo

Water-ring type Cutting Device

Function :

Select right sized plastic granules,air blower and silo is for granules storage

Packaging&Exhibition

Nā huahana huahana : Plastic Recycling Granulating Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.