Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: C250

Product Type: PVC Profile

Screw: Double-Screw

Automation: Automatic

Computerized: Non-Computerized

Certification: SGS

Customized: Customized

Packaging: film wrap and fixed in container

Nā kaʻa: Ocean

ʻO Port: Shanghai

ʻO keʻano o ka uku: L/C,T/T

ʻO Incoterm: FOB,CFR,CIF

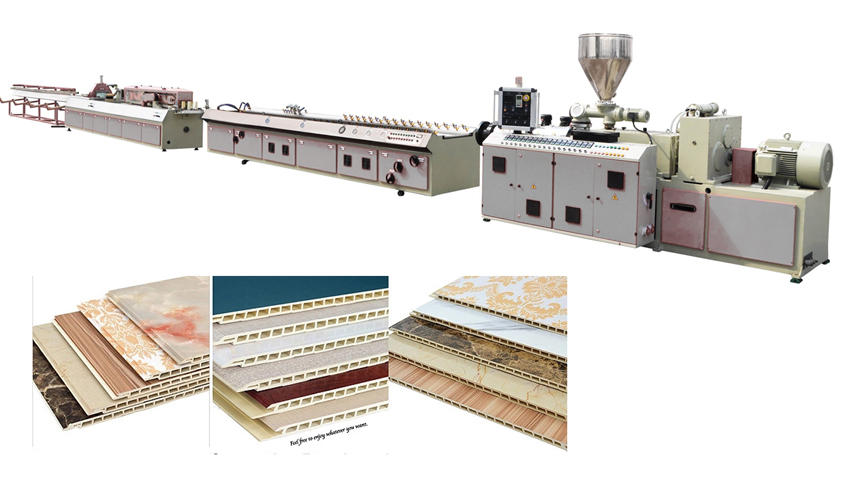

High Quality PVC/WPC Profile Panel Board Ceiling Extrusion Machine/Making Machine/Production Line

Plastic WPC PVC Profile Wall Panel Hollow Board PVC Cable Trunking Ceiling Window Door Profile Extrusion Production Line

PVC ceiling panel with width of 200mm,250mm,300mm,with different section shape and height. The surface of PVC ceiling can be treated by double color printing and coated with glossy oil, or by heat transfer printing, or by lamination, which can make marble, wooden design on the surface of products.

PVC ceiling panel is wide used in the house decoration , office decoration , kitchen room , washing room decoration , it’s environment-friendly raw materials and can be recycled use , it’s has wide market prospect .

The PVC ceiling panel making machine equip with the conical twin screw extruder , converter control system , OMRON temperature control unit , it has wide control range , accuracy temperature control and easy to operate , the auxiliary equipment consist of vacuum calibration mould & platform, hauling off machine, hot stamping machine or laminating machine , cutting machine, stack machine ,etc.

Twin screw extruder

Ceiling panel die head

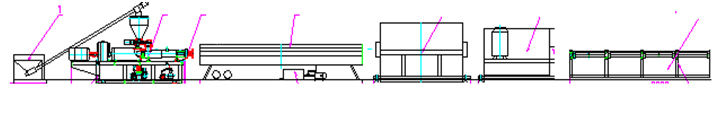

PVC ceiling panel production process : the screw feeder feed the raw materials to the mixer unit , after mix enough and the temperature reach the set temperature , the hot mixed raw materials will discharge into the cooling mixer automatically , then the spring feeder feed the mixed raw materials into the twin screw extruder , after plasticizing , extrusion and calibration , the ceiling panel will come out from the mould and follow into the cooling equipment , via the synchronous haul off machine , the ceiling panel enter the cutter , the cutter equip with the meter counter , it can cut different size according to the set length automatically .

The PVC ceiling panel making machine equip with the PID automatic simple control system , easy operate and accuracy control system , for the new investor customers , would supply the complete turn-key service , such as the capital budgets , workshop design , raw material supply and technology training . also after the production line run smoothly , we also supply the long-term technology support .

Vacuum calibration table

Technical Parameter:

|

Applicable Width |

200-250mm |

300mm |

|

Extruder |

SJZ51/105 |

SJZ55/110 |

|

Motor power(Kw) |

22 |

37 |

|

Capacity(kg/h) |

100-150 |

200-250 |

2 caterpillar haul off machine

Saw cutter

Stacking

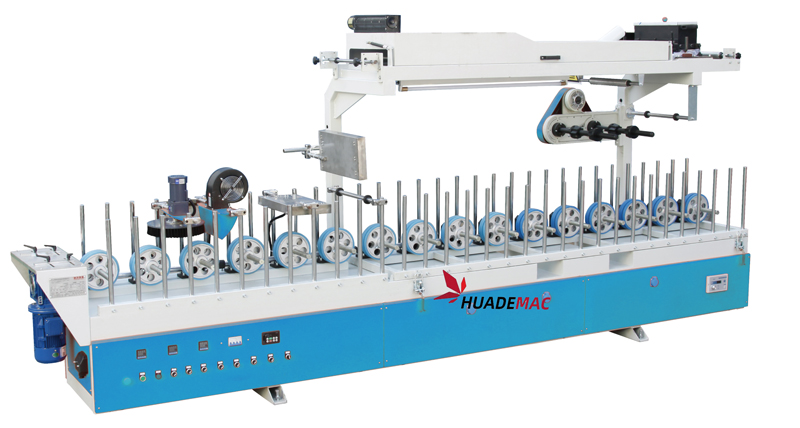

Panel surface treatment device (laminating machine )

It’s designed to laminate PVC film, decorative paper on surface of PVC board, MDF board, plastic-wood boards, extrusive profiles, windowsill and curved profiles. It’s equipped with doube-film unwinding system, magnetic powder tensioner, heating tunnel, dust cleaner, glue coating device and laminating system.

On-line laminating machine

Off-line laminating machine

PVC ceiling panel auxiliary equipment:

Nā huahana huahana : Plastic Profile Production Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.