Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: SJZ65

ʻO Brand: huade

Ka hoʻohana: Profile

Processing Plastic Type: Pvc

Kūlana: New

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 132:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Competitive Price

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Building Material Shops, Manufacturing Plant, Farms, Hotels, Home Use, Construction Works

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Gear

Packaging: plastic films wrapped

'Ohanahana: 150-200Kg/h

Nā kaʻa: Ocean

Kahi o ka hoʻomaka: china

Ka hoʻolakoʻana i ka pono: 10

Palapala: CE ISO

HS Code: 84778000

ʻO Port: shanghai

ʻO keʻano o ka uku: L/C

ʻO Incoterm: FOB,CFR,CIF,EXW

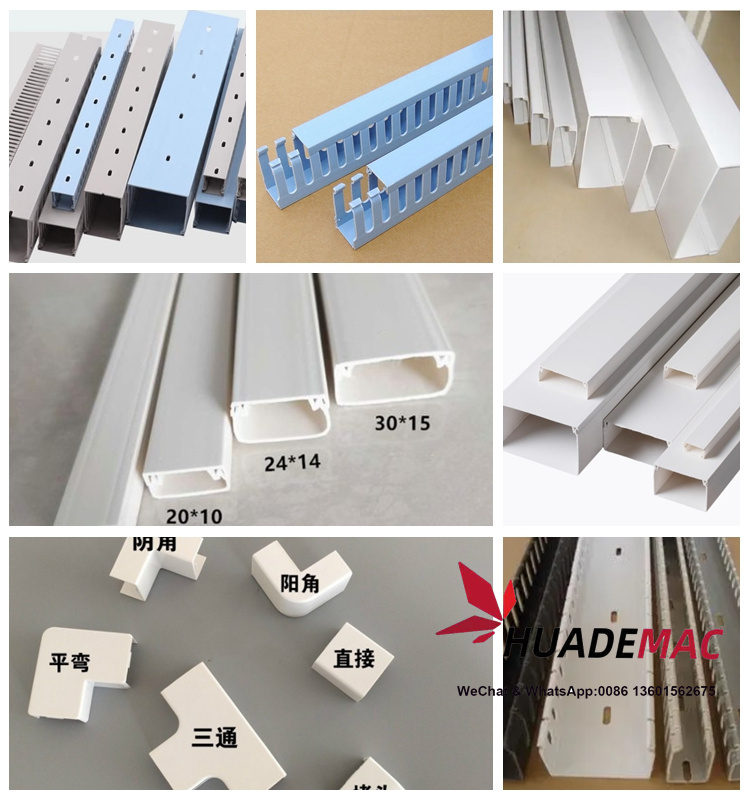

This extrusion line is applied to produce different size PVC Cable Trunking and cable trays with single cavity or two cavities.

This line can manufacture the following products by changing the molds

Door systems

Window sills

Wall and ceiling panels

Cable ducts

Roller shutter systems

Rain gutters

Sandwich panels

Plinth profiles

Curtain rails

Siding systems

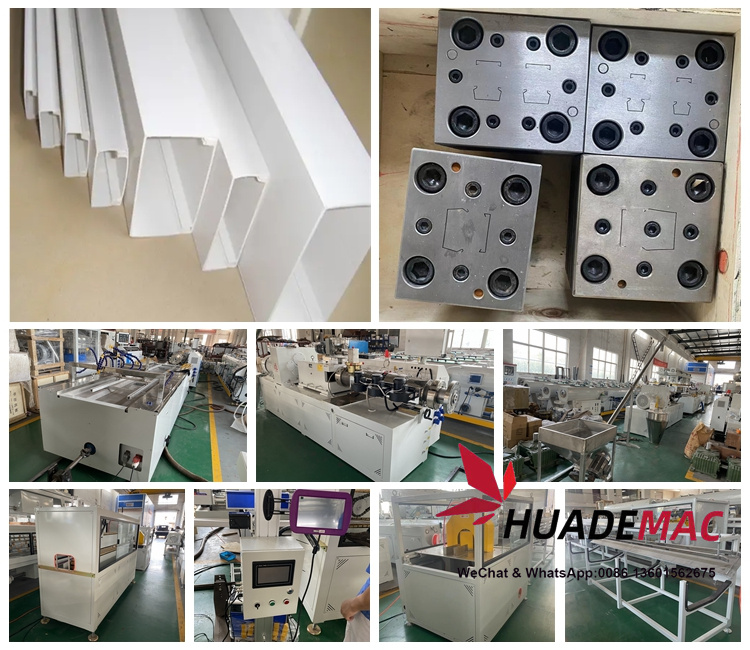

The SJSZ-series conical twin screw extruder is designed for the PVC profile application.

High flexibility in raw material combinations

Gentle and homogeneous plastifcation

Barrel with air cooling system

AC motors for low energy consumption

Control panel can be optional with PID temperature instrument or PLC touch screen

Screw diameters 55 and 65 mm

Outputs from 100 to 200 kg/h

Vacuum Calibration Table

Motor-driven height and side movement

Motor-driven longitudinal movement

Manuel tilting movement

All parts that are in contact with water is made of stainless steel

2 Caterpillar Haul-Off

Our haul-offs are equipped with two independent tracks with gearboxes with continuous speed adjustment by inverter.

Flexibility in pad dimensions

Two independent tracks with gearboxes

Speed adjustment by inverter

Saw Cutter:

Different saw dimensions for special profiles

Includes dust absorber unit

Adjustable cutting speed

Cutting width from 350 to 700 mm

Cutting height from 10 to 100 mm

Adjustable cutting speed

Tilting Table

Table material is stainless steel

Tilting system is pneumatic

Nā huahana huahana : Plastic Profile Production Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.