Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

Hoʻohālike No.: DPET75-2

Packaging: film wrap and fixed in container

Nā kaʻa: Ocean

ʻO Port: Shanghai

ʻO keʻano o ka uku: L/C,T/T

ʻO Incoterm: FOB,CFR,CIF

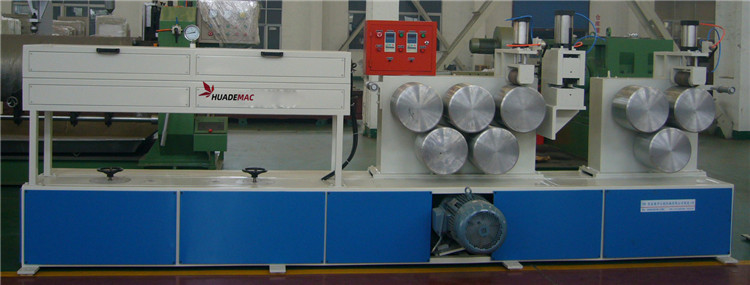

Plastic Pet Packing Strap Band Tape Extrusion Production Line

Plastic Pet PP Packing Tape Strap Band Extruder Price|Pet Strap Making Machine|Pet Strap Belt Production Line

PET packing strap is widely used, replaced for steel strap for packing application internationally, because of its good tensile strength, flexible, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc, it is used in steel, construction material, chemical fiber, paper making, tobacco, agriculture, election, etc.

Machine Features

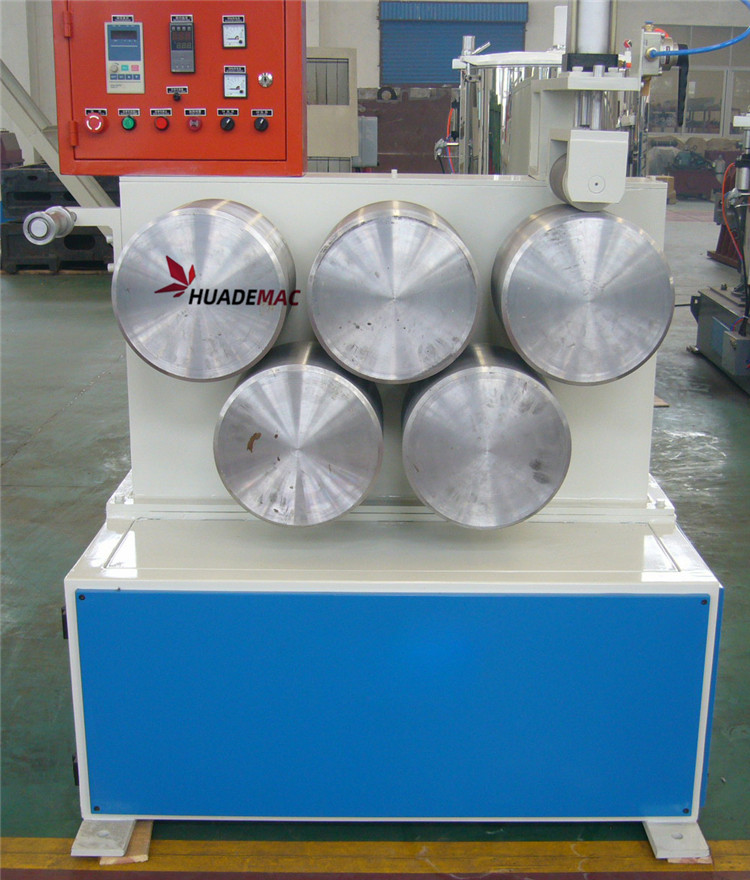

Screw with compression ratio especially for PET, gradually changing diameter and deeper thread groove at the melting part; Gearbox with hardened gears; Die can be precisely adjusted to ensure stable production and smooth surface of straps; Stainless steel cooling trough with four thermo treatment processes displaces the traditional one; Haul off rollers with bigger size ensure the quality of products; New rolling technology overcomes the shortcomings of traditional rolling machine like high gradient and bending delection; Laser embossing roller makes clear and even patterns.

PET Strap Line all parts

1--The raw material will be dried by the dehumidifier, and the below 40 dew point make the material humidity less than 40PPM and condensation polymerization;

2--The conveyor of the raw is in a enclosed and circular mode, and without contacting with the air, in order to made perfect effect of drying;

3--Special designed extruder screw for PET production, bear the better performance of material separating and mixing. Automatic material feeding provide the smooth environment for the PET strap production.

4--Special designed extrusion die & mould; And the improved screen changer realize non-stop screen changing, and without material leakage;

5--Water tank cooling the PET strap band. The steady water temperature enhance of the molecular tension strength;

6--Heating cabinet is used for thermal annealing, relief the band distortion after long-time storage;

7--Dual-station automatic winder, easy operation

We provide our worldwide customer the turn-key project. We will assist our customer from the installation to the final production of this line.

Main parameters of PET Strapping Band Production Line

|

Model |

DPET 65-1 |

DPET 75-2 |

DPET 90-2 |

|

Band number |

One |

Two |

Two |

|

Band specification |

9~19mm(Width) 0.5-1.50mm(Thickness) |

9~19mm(Width) 0.5-1.50mm(Thickness) |

|

|

Output |

50kg/h |

100kg/h |

150kg/h |

|

Water flux |

0.6 m3/h |

||

|

Water pipe diameter |

3/2″,water temp according PET strap size |

||

|

Compressed Air flux |

0.25 m3/min |

||

|

Compressed Air pressure |

0.6Mpa |

||

|

Total Power |

132kw |

186kw |

285kw |

|

The length of production line |

25-28m |

28-33m |

35-40m |

|

Power |

380V 50HZ or Customized |

||

Nā huahana huahana : PVC Conduit Pipe Production Line

Paena Pūnaewele

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.

E hoʻopihapiha i nāʻike hou aku no laila e hiki ke hoʻopili pū meʻoe wikiwiki

Hua'ōlelo pilikino: He mea nui loa kāu pilikino iā mākou.ʻO kā mākou hui pū e hoʻolaha i kāuʻike pilikino i kekahi mauʻaeʻia.