Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 50-200mm

Packaging: Wooden Pallet

Transportation: Ocean

Port: Shanghai Port

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

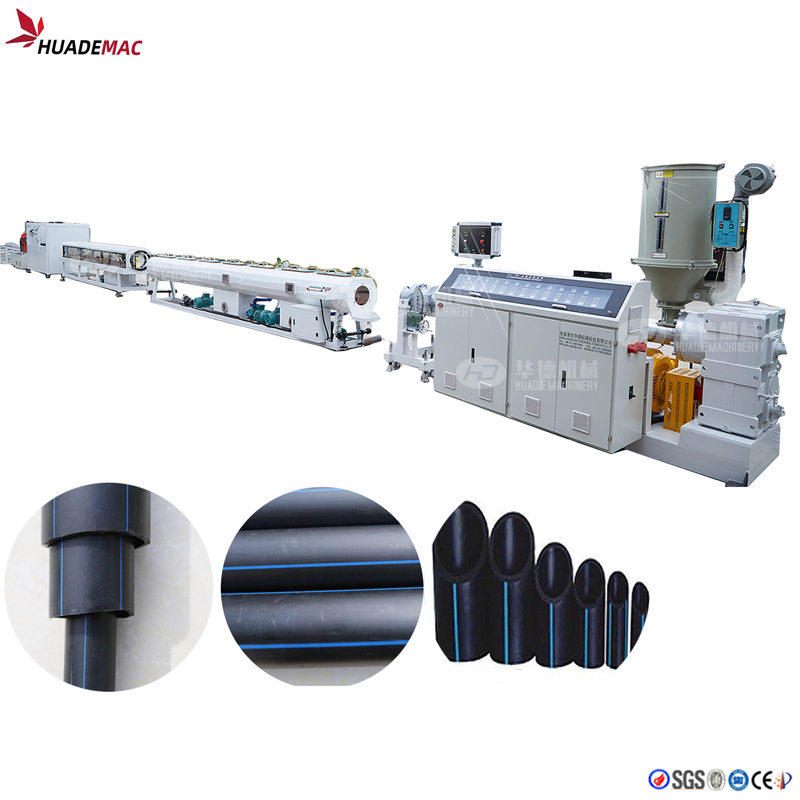

PE HDPE PPR plastic pipe making machine

PE series Plastic Pipe Production Line is mainly used for producing pipe of waster supply and drainage in the field of agriculture and sonstruction cable etc. This machine consists of Vacuum Calibration Tank, haul off unit. Cutting unit, stacker etc. The single screw extruder and haul off unit apply famous A/C frequency conversion speed regulation device, both vacuum pup and driving motor apply famous brand. The haul-off unit includes two-claw type, three-claw type, four-claw type, six claw type, eight-claw type, ten-claw type, twelve-claw type etc. Dust free cutting machine, saw blade cutting machine or planetary cutting machine can be applied, the property of machine group is reliable. The production efficiency is high with special device, It can produce inner wall spiral pipe, inner wall hollow pipe, and core layer foam pipe. It can also produce PP, PE, ABS, PPR, PEX, Silicon core pipe etc. The planetary cutting machine is controlled automatically with computer, it has such asvantages of simple operation, reliable performance etc. It has reached international advanced level.

Process

material Hopper → PE pipe extruder → marking line extruder → mould → calibrator → vacuum calibration tank → spray cooling water tank → printer → haul-off → cutter → pipe discharging rack

Features

1. The extruder of HDPE pipe line adopt high efficiency screw & barrel, the gearbox is hardening teeth gearbox with self-lubrication system. The motor adopt Siemens standard motor and speed controlled by ABB inverter. The control system adopts Siemens PLC control or button control.

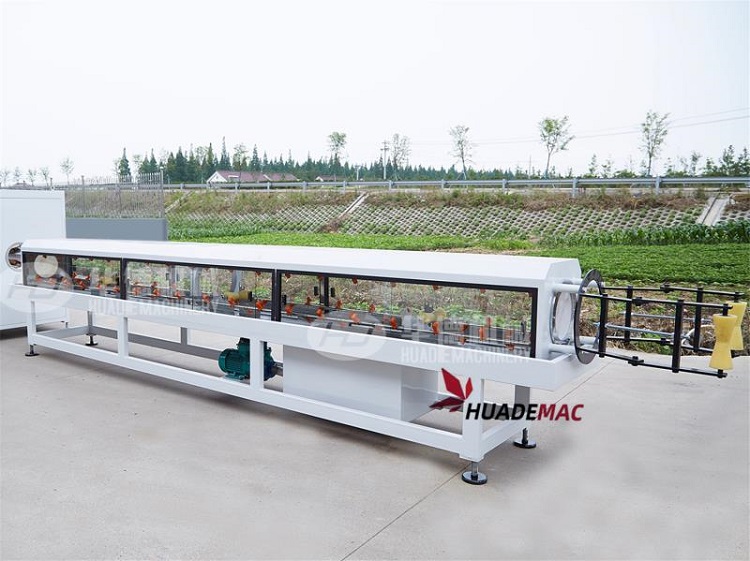

2. This PE pipe line is composed by material charger+ Single screw extruder + pipe mold + vacuum calibration tank + spraying cooling tank x 2sets + three Caterpillar Haul-off Machine + no-dust cutter+ stacker.

3. The tank body of vacuum calibration tank adopt two chamber structure the vacuum calibration and cooling parts. Both of vacuum tank and spraying cooling tank adopt stainless steel 304#. The excellent vacuum system ensures the precise sizing for pipes; spraying cooling will improve the cooling efficiency; Auto water temperature control system make the machine more intelligent.

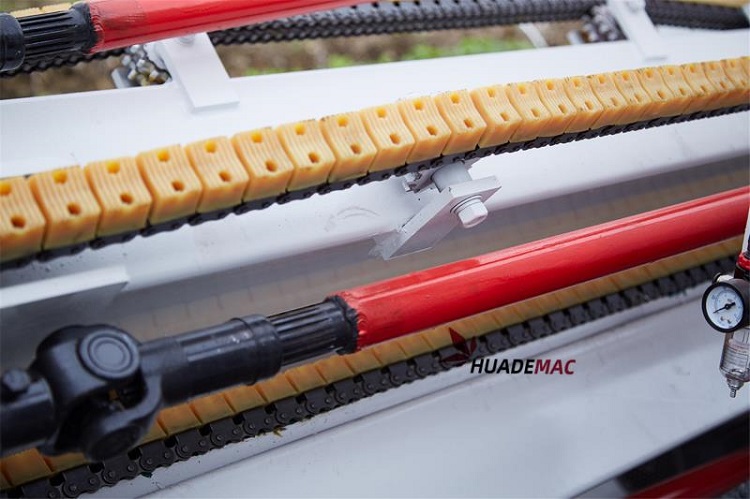

4. The Haul-off Machine of this pipe line will adopt caterpillars type. With meter code, it can count the pipe length during the production. Cutting system adopt no-dust cutter with PLC control system.

PE HDPE PPR plastic pipe making machine

SJ65/33 of Pe Pipe Production Line

Vacuum of PE Pipe Production Line

Spray of PE pipe production line

Three claw haul-off of PE pipe production line

Knife-lift cutter of PE pipe production line

Stacker of PE pipe production line

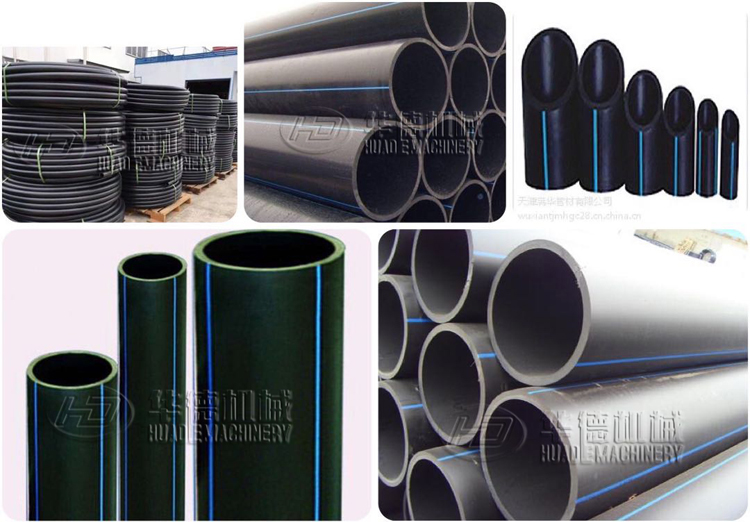

Final Products

Packaging of PE pipe production line

Exhibition of PE pipe production line

Product Categories : HDPE PP Pipe Extrusion Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.