Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 700-1100MM

Application: Film, Profile

Status: New

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 132:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Philippines, Kenya, Argentina, South Korea, Chile, Ukraine

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: High Productivity

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Philippines, Malaysia, Australia, Chile, Kyrgyzstan

Applicable Industry: Hotels, Building Material Shops, Manufacturing Plant, Farms, Construction Works

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Bearing, Engine

Transportation: Ocean

Port: SHANGHAI

Payment Type: L/C,T/T,D/P

Incoterm: FOB

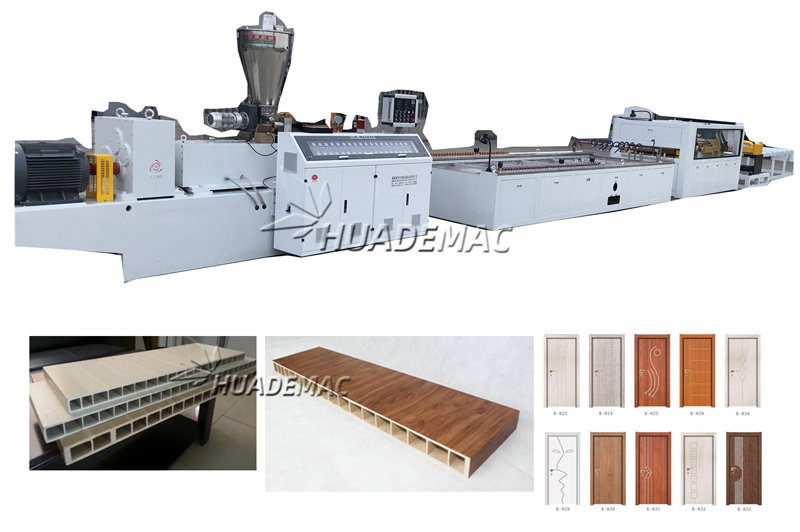

PVC WPC door board machine production line

PVC WPC door board machine production line is mainly used for making wpc door board with different width and thickness. The surface of door board can be treated by printing & coated with glossy oil, heat transfer printing or lamination, which can help the door panel get good decorative effect for house door, kitchen,toilet,balcony and so on.

Related machine:

1.mixing unit

2.door frame making machine

3.door frame hot stamping and lamination machine

4.door board hot stamping and lamination machine

| Model | Max.wide (mm) | Extruder model | Max.output(kg/h) | Motor power(kw) |

| HD600 | 600 | SJZ80/156 | 280 | 75 |

| HD800 | 800 | SJZ80/156 | 280 | 75 |

| HD900 | 900 | SJZ92/188 | 600 | 132 |

| HD1000 | 1000 | SJZ92/188 | 600 | 132 |

| HD1200 | 1200 | SJZ92/188 | 600 | 132 |

Photos

Extrude↓

Function :

Heat and extrude the pvc to the mould for door board shaping.

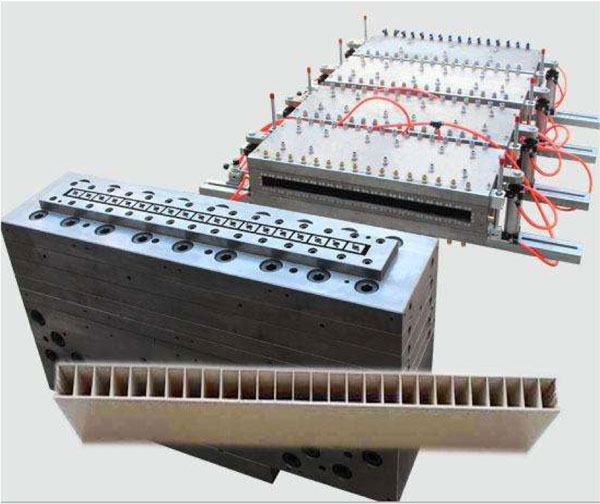

mould↓

Function :

The board width and thickness are all custmoized

Calibration table↓

Function :

Cooling and finalize the shape of the profiles

Haul-off↓

Function :

Pull the wpc door board in a uniform speed

Cutting machine↓

Function :

Cut the wpc door board into fixed length pieces

Stacker↓

Function :

Stacking the finished product

Hot stamping and lamination machine↓

Function :

this machine is used to print different pattern on the surface of the board

to make it looks more like real wood

Product↓

Packaging&Exhibition

Product Categories : Plastic Board Sheet Production Line

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.