Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SJ80

Application: Granules

Processing Plastic Type: Pe, Pp, Pet, Hdpe, Ppr, Hdpe/Pp, Pe/Pp, Ldpe

Status: New

Screw Design: Double-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 132:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Energy Saving

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Garment Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Retail, Food &Amp; Beverage Shops, Advertising Company

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Pump, Gearbox, Screw

Packaging: Wooden Pallet

Transportation: Ocean

Port: Shanghai Port

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Plastic Recycling Pellet Making Granulator Machine

1. This PVC pelleting production line is composed by a conical twin-screw extruder and the correspondingly pelletizing downstream equipment, it is suitable for the pelletizing of PVCraw materials with wood powder or other additives. 2. The pelletizing downstream equipment is the die face cutter, air transferring unit, vibration separating and cooling unit. This pelletizing downstream equipment has the features of high automation and high production efficiency. 3. The screw and barrel, made of 38CrMoAlA , are made through smithing, tempering, double aging, nitriding treatment. Differences from others: screw edge is tempered after rough finish with good harden ability, and double aging reduce efficiently stress. Meanwhile, through accurate processing, phases of the screw edges have small error. The barrel and screw have high universal property. The structure of screw is different to different materials.

Specifications:

1.Client reference

2.Capacity:100-1000kgh

3.Pellet size: Diameter: 2.5 to 3mm

The process flow of PVC pelletizing line as following:

Screw feeder →Side force feeder→ Extruding system1→High speed screen exchanging→Extruding system2 →High speed screen exchanger →water cooling bath→ air dryer→ pelletizer machine→ Silo

Our machine can recycle

PVC hot cutting pelletizing machine photos

Conical Twin Screw Extruder

Die Head and Hot Cut Pelletizer

Vibrating Sieve

Air cooling & Storage Bin.

Final Products

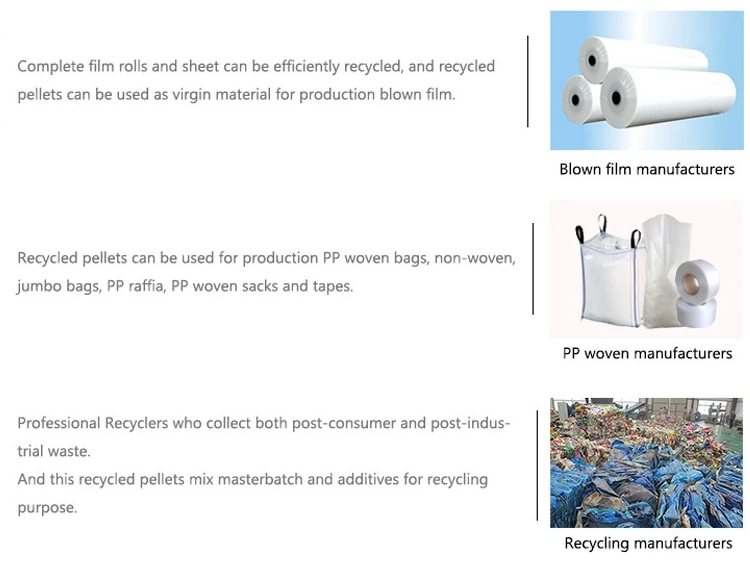

Recycled pellets application industry

Other Products

Zhangjiagang Huade Machinery

Packaging

Product Categories : Plastic Recycling Granulating Line

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.