Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 30-50mm

Packaging: Wooden Pallet

Transportation: Ocean

Port: Shanghai Port

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

PVC ceiling panel Profile Production Line

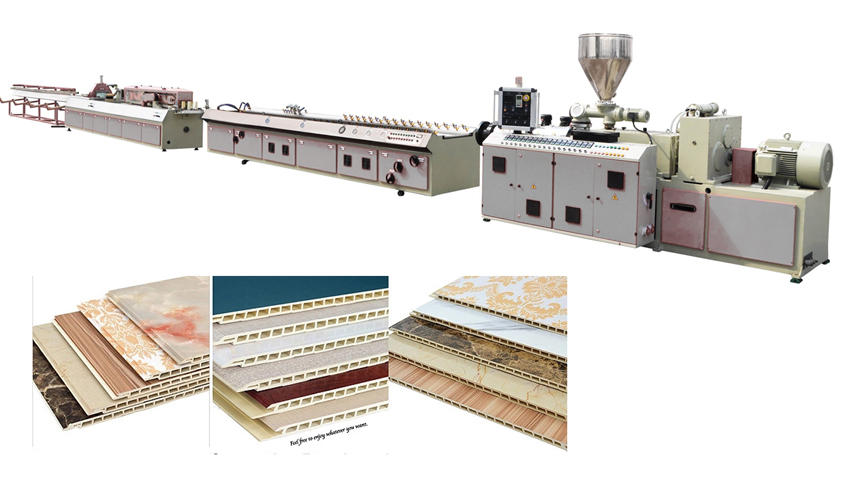

The working process of PVC ceiling making machines: Raw material → mixing → feeder→ double screw extruder → mold → vacuum calibration table → (hot stamping) → haul-off unit → cutting machine → stacker

PVC Ceiling Making Machines

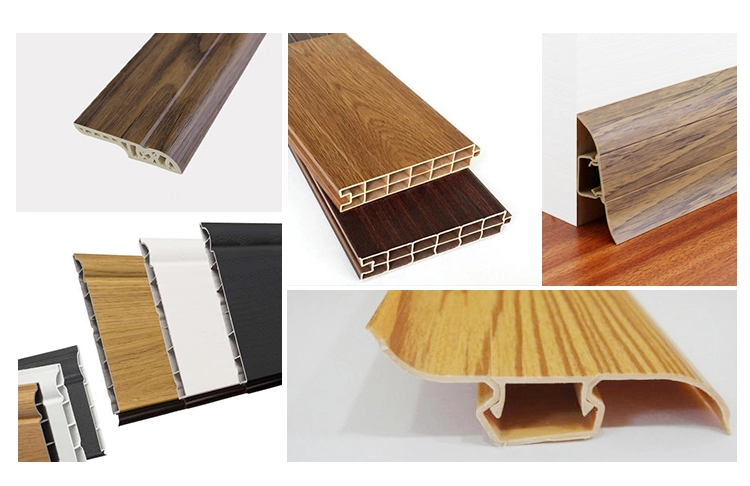

(1) It is mainly used for making PVC/UPVC profile, ceiling, panel for decoration with different profile break-section moulds.

(2) It can also produce Wood+ PVC profiles with different screws in the extruder.

The production line includes auto feeder, plastic extruder, mould, vacuum forming table, haul off unit, auto cutting machine, stacker.

Auxiliary equipments: mixer, crusher, pulverizer, lamination machine, hot stamping machine, printing machine, air compressor and so on.

PVC ceiling panel profile production line photos

Twin screw extruder

Ceiling panel die head

Vacuum calibration table

2 caterpillar haul off machine

Saw cutter

Final products

Other products

Packaging

Zhangjiagang Huade Machinery

Product Categories : Plastic Profile Production Line

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.