Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 500

Automation: Automatic

Computerized: Computerized

Certification: ISO9001:2008

Condition: New

Transportation: Ocean

Port: SHANGHAI

Payment Type: T/T,D/P

Incoterm: FOB

Plastic PP PE Bottle Recycling Line

This pp pe bottle recycling line is widely used for waste rigid plastic HDPE bottle, PP kettle, etc.

The waste dirty material go through crushing, washing, drying, and collecting process will turn to be clean flakes for pelletizing.

We also supply Plastic Pelletizing Line / plastic granulator to make the clean flakes into pellets (granules). The renewable pellets (granules) can be made into plastic barrel, plastic pipe, plastic frame, farm implement, machine components, and so on through extruding forming machine.

They are widely used in agriculture, construction, industry and our daily life. In this way, we achieve the reuse of waste plastic recycling and the purpose of protecting our environment.

Belt conveyor

To convey the waste into crusher

Crusher

Crush waste plastic bottle to suitable size. Good for washing and drying.

Friction Machine

Remove dirt or sand by friction paddles with or without water.

Hot water washing tank

It use hot water to wash the oil and chemical polution

Floating washing tank

Wash away dirt with stirring paddles

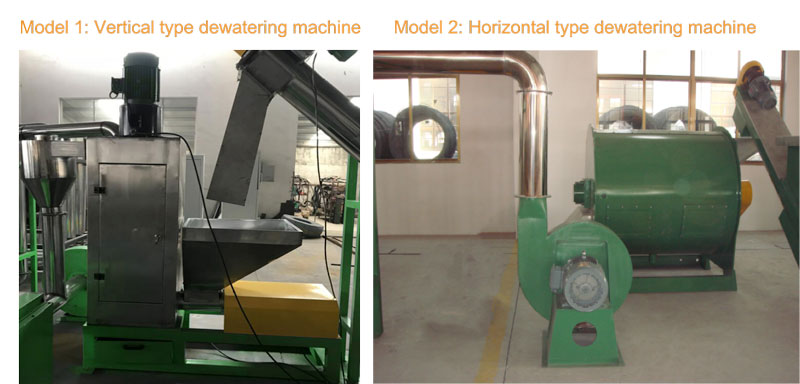

Dewatering machine

Dry the crushed cleaning rigid plastic scraps after washed

Hot air dryer pipe

Further Drying washed rigid plastic scraps

Belt conveyor: conveying dirty plastic bottles into crusher.

If too much scrap iron, metal detector may be needed.

Crusher: with water, cut plastic bottles into small size

Friction washing loader machine: washing out the sand, soil and loading the material

Floating washing tank: washing out the dirty from the material

Screw loader: load bottle flakes into the next step

Horizontal friction dewatering machine: washing out labels, dirty and remove dirty water

Floating washer tank: washing out the dirty from the material

Screw loader: load bottle flakes into the next step

Dewatering machine: remove the water from the material

Hot air drying system: drying the bottle flakes

Storage hopper: collect the flakes

Control cabinet: control the line on/off (famous brand such as Schneider, Siemens, etc.)

From Waste bottle to washed flakes

Packaging&Exhibition:

Product Categories : Plastic Recycling Washing Line

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.