Bayaanka Asturnaanta

Tusaale ahaan.: 20-63mm

Codsiga: Pipe

Processing Plastic Type: Pe, Pp, Ppr, Hdpe/Pp, Pe/Pp

Xaaladda: New

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 65

Screw Length To Diameter Ratio: 33:1

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Energy Saving

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Garment Shops, Machinery Repair Shops, Food &Amp; Beverage Factory, Printing Shops, Food &Amp; Beverage Shops, Advertising Company

Marketing Type: New Product 2020

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Pump, Gearbox, Screw

Baakadaha: Wooden Pallet

Gaadiidka: Ocean

Port: Shanghai Port

Nooca Bixinta: L/C,T/T

Madadaalo: FOB,CFR,CIF,EXW

Production Line PPR Pipe Making Machine

1.Application Hot water supply

2.Siemens PLC computer control

3.Pipe diameter: 20mm-63mm

4.Speed:12m/min

The glass fiber PPR Pipe making machine main components includes :PPR Extruder, Glass fiber Extruder, Marking line Extruder, Die head mould, Vacuum calibrating tank, Water cooling tank, haul off machine, Cutting machine, Electrical cabinet

Features of Product:

· 1)Specialized fiber glass reinforced plastic extruder with double metal screws and barrel ,ensuring both high speed extrusion and long service life of the extruder.

· 2)Composite extrusion head of special design, ensure uniform thickness of three layers, and thickness of each layer can be adjustable.

· 3)Compare to common PP-R material, extruded material by this production line has features of high compression strength, no deformation in high temperature, no bending and very small longitudinal reversion rate. Furthermore, its cost is about 5%~10% cheaper than other tubes, it eliminated serious fault of common PP-R tubes which will be deformed while carrying hot water.

Production Line PPR Pipe Making Machine process

Drying of raw materials→ Extrusion molding → Vacuum sizing → Spray cooling → Haul-off → Fixed length cutting → Pipe filling and unloading

Production Line PPR Pipe Making Machine photos

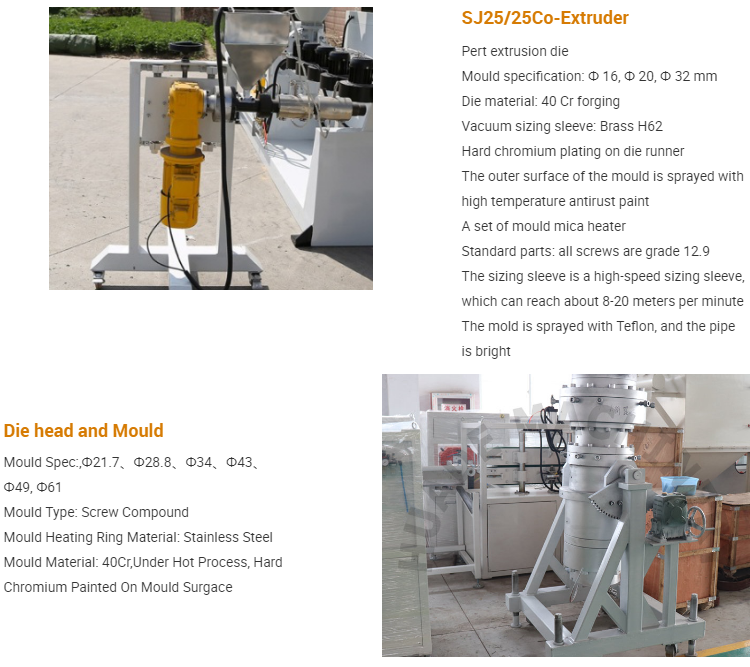

SJ65/33 extruder of Production Line PPR Pipe Making Machine

1. Single screw extruder: model SJ65 / 33

2. Cylinder and screw material: 38CrMoAlA,

3. Cylinder and screw structure: barrier screw, asymmetric slotted barrel design.

4. The gearbox is equipped with strong thrust bearing and high torque output; the gear is made of special alloy, with hard tooth surface and gear grinding process;

5. Temperature control table of OMRON

6. ABB or Siemens brand inverter

7. Schneider or Siemens AC contactor

8. Siemens Bede motor

9. Diameter of screw: Φ 65mm

10. Length diameter ratio of screw: 33:1

11. Driving motor power: 55kW high speed screw

12. Gearbox: high torque, low noise, hard tooth surface grinding reducer is equipped with external cooling circulation system

![%X7]3_3)P1F`Z8)H{P$IZ46 %X7]3_3)P1F`Z8)H{P$IZ46](http://bsg-i.nbxc.com/product/57/e5/10/3661ccf114bb06b4874e588f2c.png)

![26}0CO[_{GNS}`PP]SIBIIY 26}0CO[_{GNS}`PP]SIBIIY](http://bsg-i.nbxc.com/product/22/8d/4d/e5a4b9ed2d7fee3d7f08c337fb.png)

![{]LTKZG95X7S6RQ%DXL%WK2 {]LTKZG95X7S6RQ%DXL%WK2](http://bsg-i.nbxc.com/product/cb/b5/15/da52f89af72edfdc4caceac211.png)

![3W]E40_WY3WCSFWB%U0%~]L 3W]E40_WY3WCSFWB%U0%~]L](http://bsg-i.nbxc.com/product/03/44/5d/d88d430f785326d5d986008ea0.png)

Packaging of Production Line PPR Pipe Making Machine

Exhibition of Production Line PPR Pipe Making Machine

Qaybaha alaabta : PPR PPRC Pipe Extrusion Line

Site Mobile

Bayaanka Asturnaanta

Buuxi macluumaad dheeri ah si markaa si dhakhso leh ula xiriiri karto

Bayaanka Asturnaanta